Shenyang Dongbo Thermal Technology Company is a specialized manufacturer of vacuum heat treatment furnaces and vacuum metallurgical equipment, focusing on precision heat treatment, surface modification technologies, and special metal melting solutions. With a strong emphasis on R&D, manufacturing, and process innovation, we provide advanced thermal treatment solutions for industries requiring high-performance metal treatment.

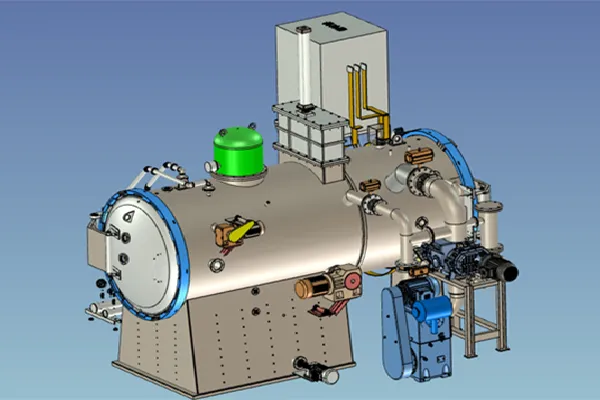

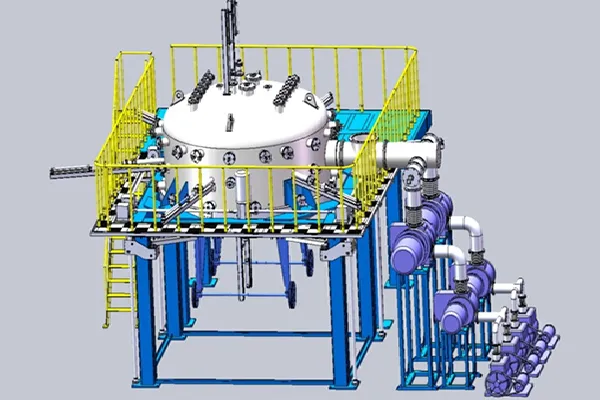

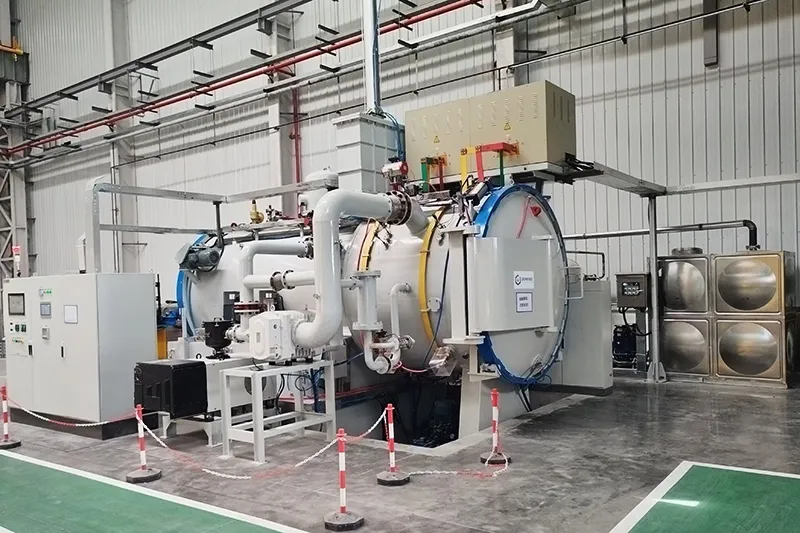

At Dongbo, we have developed a comprehensive range of vacuum heat treatment and metallurgical equipment, categorized into 16 major product lines, 46 models, and over 200 specifications. We offer a comprehensive range of vacuum heat treatment and metallurgical equipment, including low-pressure vacuum carburizing & carbonitriding furnaces, high-pressure gas nitriding & nitrocarburizing furnaces, vacuum quenching, sintering, brazing, tempering, annealing, and metallizing furnaces, vacuum hydrogen furnaces, vacuum heat treatment lines, and vacuum furnace control system to meet diverse industry needs. Our technologically advanced vacuum treatment solutions are designed to meet diverse market demands while offering customized configurations for specialized applications.

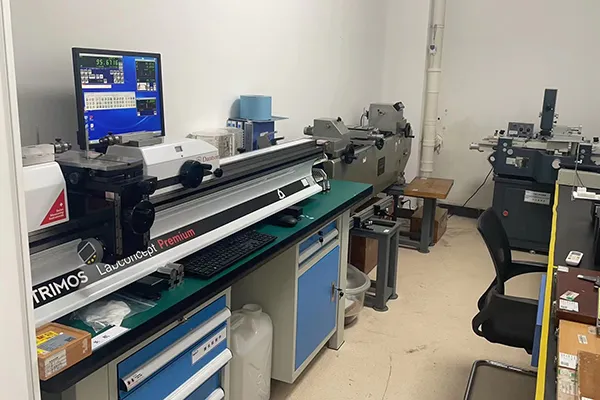

To drive continuous innovation, we have established a three-dimensional vacuum heat treatment simulation platform, an expert process R&D center, and a mechanical and intelligent control system development base. We utilize specialized simulation and analysis tools, including Thermo-Calc, Deform, and Ansys, along with a comprehensive set of over 30 microstructure analysis instruments such as SEM, EPMA, and TEM. Additionally, our material testing laboratory is equipped with tensile, impact, friction wear, and fatigue testing systems, ensuring that our vacuum treatment solutions meet the highest performance and reliability standards.

We are committed to pushing the boundaries of vacuum heat treatment technology, delivering high-precision, energy-efficient, and intelligent solutions to industries worldwide.

Since its establishment, Dongbo has successfully completed multiple national-level scientific research projects, achieving significant breakthroughs in surface treatment, microstructure control, and special metal melting technologies. We have developed a full-chain equipment R&D platform, covering the entire process from theoretical modeling and equipment structure simulation to prototype design, process validation, software optimization, and system integration. With over 20 patented inventions and software copyrights, we continue to drive innovation in vacuum heat treatment furnaces and vacuum metallurgical equipment. We have also obtained ISO9000-2015 and IATF16949-2016 quality management system certifications, ensuring that our heat treatment furnaces meet strict international quality standards.

Through continuous innovation and development, we have established a strong technological advantage in vacuum heat treatment and specialized metallurgical processing, such as low-pressure vacuum carburizing system, breaking long-standing foreign monopolies in this field. This technology enables precise carburizing for high-alloy materials, with proprietary advancements including an intelligent process expert system, dynamic carbon flux adjustment technology, hardness gradient flexible control, high-temperature carburizing capabilities, and an unmanned intelligent operation system. The developed vacuum carburizing furnace has been widely adopted in aerospace, rail transportation, automotive, and robotics industries, solving critical technical challenges for RV reducer cycloidal gears in robotics, stainless steel clamps for high-speed rail, and high-end bearings for aerospace engines.

In specialized heat treatment, we have developed low-temperature carburizing, chromium nitriding, and aluminum oxidation diffusion furnaces, which have been successfully applied in China’s nuclear industry, contributing to the localization of production equipment. Our advanced melting and precision casting equipment provides technological and equipment support for improving the performance of core components in aerospace engines.