Industry Applications of Vacuum Heat Treatment Furnaces

Dongbo provides vacuum heat treatment furnaces for the automotive industry, ensuring precision and durability for components such as gearwheels, bearings, shafts, rings, and bushings.

In automotive manufacturing, process reliability, efficiency, and repeatability are essential. Our vacuum heat treatment solutions focus on minimizing deformation, reducing process costs, and shortening cycle times. The use of efficient carburizing techniques ensures consistent product quality while contributing to the reduction of CO₂ emissions. With advanced technology and a focus on precision, our vacuum heat treatment solutions meet the rigorous demands of the automotive sector, enhancing component performance and production sustainability.

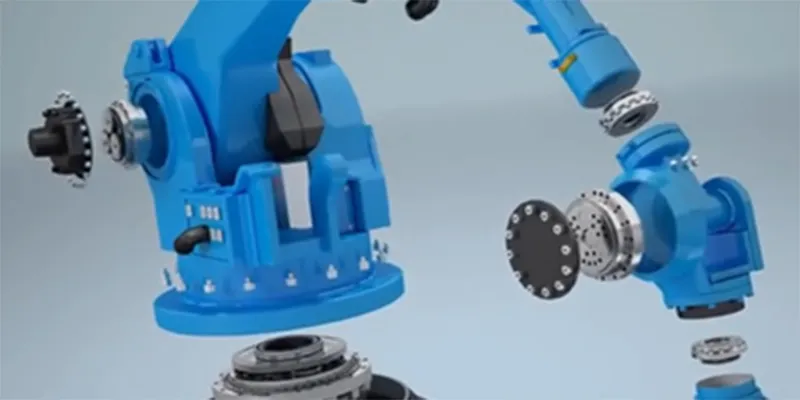

The vacuum heat treatment equipment is widely used in the automotive manufacturing industry, enhancing the hardness, wear resistance, fatigue strength, and service life of key components.

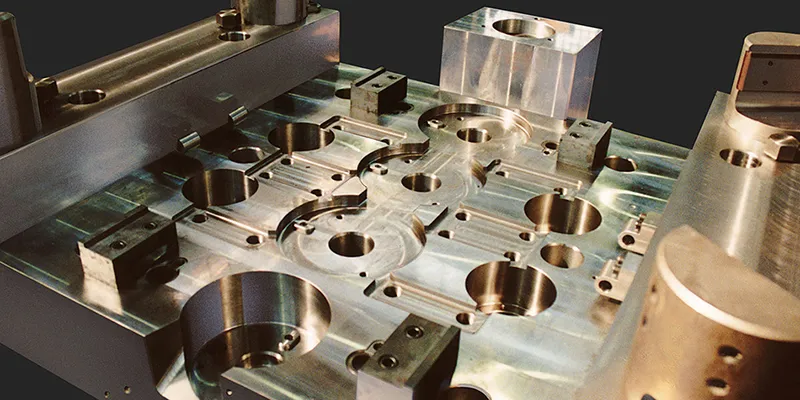

Components that Can Be Processed

- Coils

- Heat Exchangers

- Gears

- Battery Coolers

- Fuel Injection Nozzles

- Machine Parts

- Tools & Dies

- Fasteners

- Bearings

Recommended Products

-

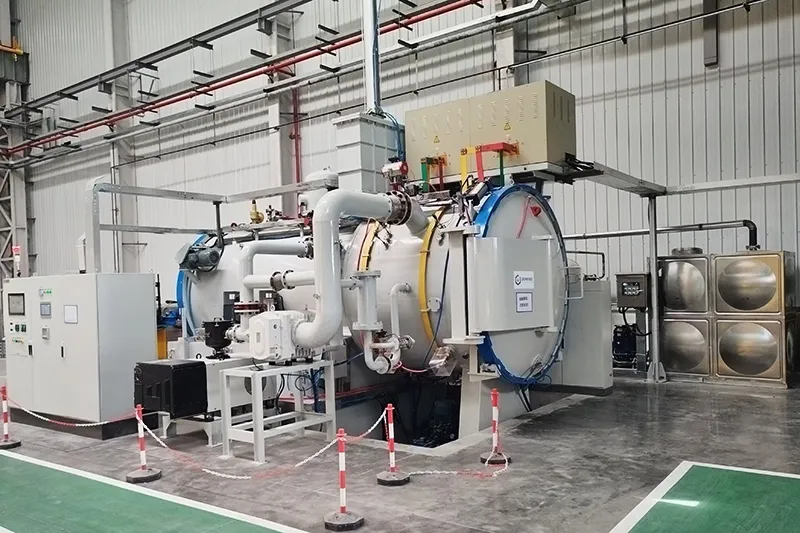

- Low Pressure Vacuum Carburizing Furnace

- Carburizing prediction error reduced from 20% to 5%, achieving over 95% accuracy

- Minimized carbon black formation for cleaner processes and improved carburizing layer structure

Vacuum Heat Treatment Line

The vacuum heat treatment line integrates multiple heat treatment processes, including vacuum carburizing, high-pressure gas quenching, tempering, and cleaning, ensuring efficient and flexible production for automotive components. The vacuum low-pressure carburizing line meets the demanding requirements for high fatigue strength and wear resistance in automotive shaft and gear components, ensuring precision and consistent quality in every process.

-

- Vacuum Brazing Furnace

- Max. load capacity (kg): 1000-3000

- Max. temperature (℃): 700

-

- Vacuum Tempering Furnace

- Max. load capacity (kg): 200-1200

- Max. temperature (℃): 750

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555