- Process Control

- Specifications

- Key Advantages

- High-Pressure

Process Control

The process program database is generated by a process simulation system based on factors like material composition and desired case depth. Each program is validated through production trials. The automated control system ensures precise regulation of nitriding temperature, gas pressure, and gas flow, guaranteeing that the nitriding or nitrocarburizing process meets all technical requirements with high accuracy and consistency.

Specifications

| Model | DB-SNG644H | DB-SNG755H | DB-SNG966H | DB-SNG1266H | DB-SNG1299H |

| Effective internal dimensions (mm) | 600×400×400 | 700×500×500 | 900×600×600 | 1200×600×600 | 1200×900×900 |

| Max. load capacity (kg) | 200 | 300 | 500 | 800 | 1200 |

| Heating power (kW) | 50/65 | 65/85 | 90/120 | 120/160 | 180/240 |

| Max. temperature (℃) | 1100/1320 | 1100/1320 | 1100/1320 | 1100/1320 | 1100/1320 |

| Ultimate vacuum level (Pa) | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ |

| Temperature uniformity (℃) | ±5 | ±5 | ±5 | ±5 | ±5 |

| Max. gas quenching pressure (bar) | 6 | 6 | 6 | 6 | 6 |

| Pressure rise rate (Pa/h) | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 |

Note: The above parameters are for the standard horizontal single-chamber gas quenching high-pressure gas nitriding multi-functional vacuum furnace. We can provide customized, non-standard designs and manufacturing to meet specific customer requirements, such as achieving an ultimate vacuum level of 10⁻⁴ Pa or higher and a pressure rise rate better than 0.1 Pa/h.

Key Advantages

- The fully sealed vacuum furnace design eliminates open flames, explosion risks, and ammonia odors, ensuring a cleaner and safer work environment.

- The system allows for immediate start and stop operations, ensuring flexible heat treatment cycles.

- Utilizes direct heating elements for faster temperature rise and energy savings.

- Features an adjustable ammonia gas pressure range of 4×10⁻¹ to 5×10⁵ Pa, ensuring uniform nitriding even in small holes, deep holes, and blind holes, with consistent depth and hardness across all surfaces.

- Supports both high-pressure gas cooling and oil quenching, preventing tempering brittleness in alloy structural steels and eliminating defects such as needle-like precipitates.

- Ensures high-quality finishes and reduced deformation after treatment.

- Reduces operational costs by minimizing atmosphere consumption and shortening nitriding cycles.

- Dual-system for enhanced diffusion

Heating and surface purification are conducted under a 4×10⁻¹ Pa vacuum

Nitriding is performed under 0.1–0.5 MPa ammonia pressure

Diffusion is carried out under 4×10⁻¹ Pa vacuum for better white layer control

- Supports multiple processes, including gas nitriding, gas nitrocarburizing, vacuum tempering, vacuum annealing, vacuum aging, and vacuum high-pressure or oil quenching, enhancing efficiency and reducing equipment and labor costs.

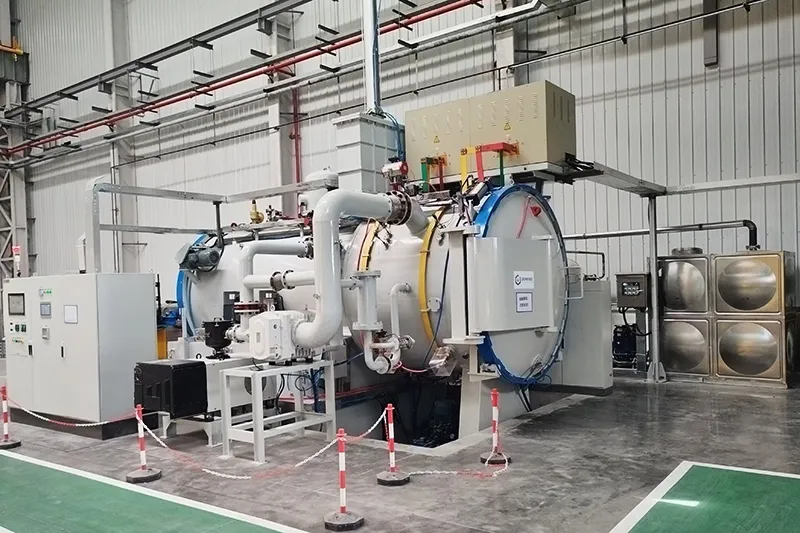

High-Pressure Gas Nitriding (Nitrocarburizing) Heat Treatment Line

We offer configurable material handling systems that integrate multiple vacuum high-pressure gas nitriding furnaces, vacuum tempering furnaces, and various cleaning machines into a comprehensive heat treatment line. This setup is designed to meet the demands of large-scale nitriding or nitrocarburizing production, ensuring efficient, streamlined, and high-capacity processing.

Our Featured Vacuum Furnaces