Contact us for more details about our vacuum heat treatment furnaces.

-

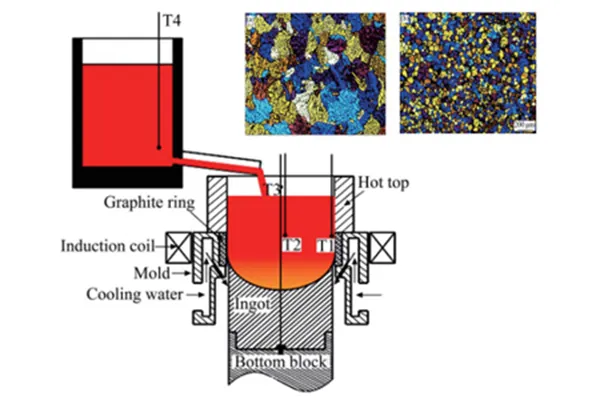

- EMS Vacuum Precision Casting Refining Furnace

Our electromagnetic stirring (EMS) vacuum precision casting refining furnace is a three-chamber, semi-continuous system integrating high-temperature alloy melting, casting, precision casting, and electromagnetic oscillation. This advanced vacuum refining equipment is primarily used for the melting and precision casting of iron-based, nickel-based superalloys, and other metal materials.

View Details

-

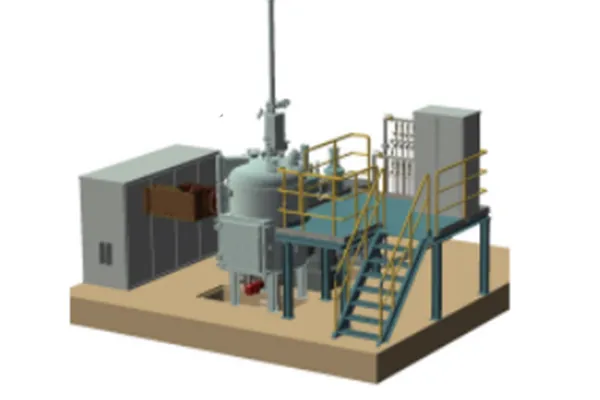

- Vacuum Directional Solidification Furnace

Our vacuum directional solidification furnace (DB AI-VIM-DC) is an advanced vacuum refining system that integrates high-temperature alloy melting, casting, precision casting, and directional solidification. It is designed for the melting and precision casting of iron-based, nickel-based superalloys, and other metal materials, supporting the production of columnar and single-crystal components through specialized precision casting processes.

View Details

-

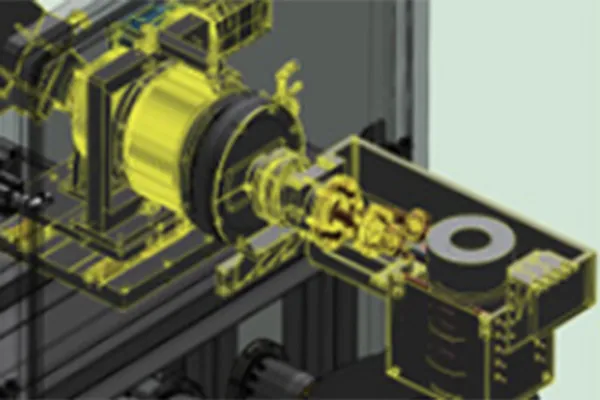

- Suspension Smelting Furnace

Our water cooled copper crucible suspension smelting furnace is an advanced vacuum refining system integrating high-temperature alloy melting, bottom pouring/tilting casting, and precision casting. The furnace utilizes a segmented water-cooled copper crucible as the base, where an intense electromagnetic field induced by the coil enables the metal to be melted in a semi-suspended or fully suspended state.

View Details

-

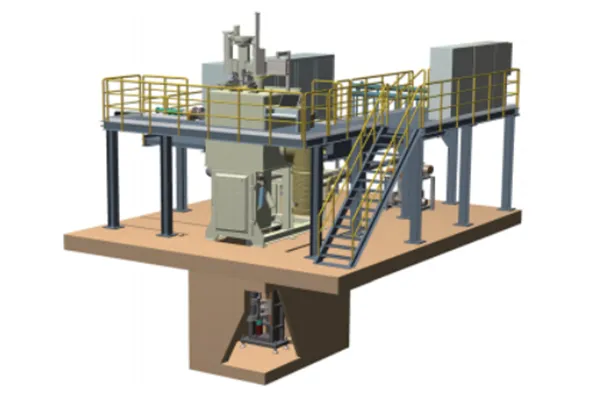

- Vacuum Precision Casting Furnace

Our multi-function vacuum precision casting furnace is a three-chamber, semi-continuous vacuum refining system that integrates high-temperature alloy melting, casting, and precision casting. It is designed for the efficient and continuous production of iron-based, nickel-based superalloys, and other high-performance metal materials.

View Details