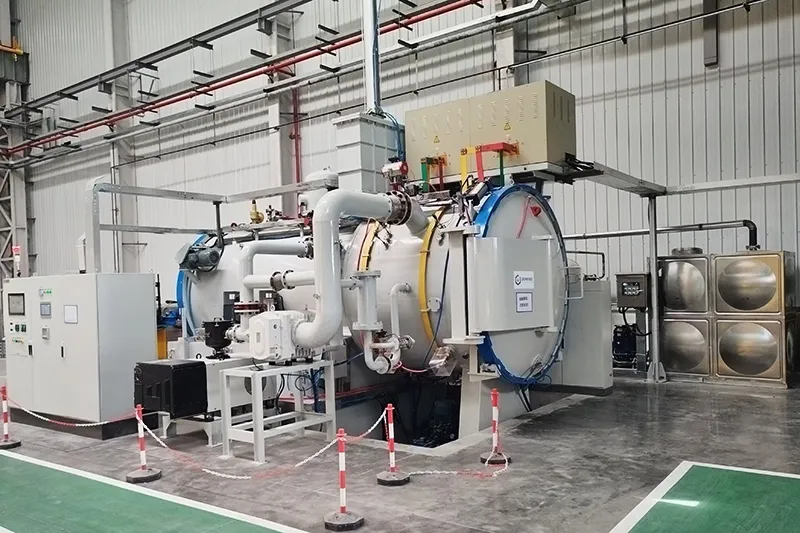

Contact us for more details about our vacuum heat treatment furnaces.

We are dedicated to providing comprehensive service for customers looking to optimize their vacuum carburizing processes. From initial testing to final equipment selection, we ensure a smooth and efficient experience.

Before purchasing any of our heat treatment lines or equipment, customers can visit our installations to conduct vacuum carburizing trials, including small-scale and batch production tests. Once we receive the workpieces and both parties confirm the process requirements, our team guarantees to complete the carburizing trials within five days. After reviewing the test results, we discuss the equipment specifications to finalize the details and establish a collaborative agreement.

During this phase, our team works closely with customers to finalize equipment specifications, optimize configurations, and provide guidance on integrating the furnace into their production process. Every detail is carefully reviewed to avoid complications during installation and operation. Once the purchase is finalized, customers receive detailed training and operational guidance to ensure smooth implementation. Each of our heat treatment solutions is designed for intuitive operation, allowing users to manage processes efficiently without the need for extensive adjustments. Remote monitoring and technical support are also available to assist with troubleshooting and ensure that production remains uninterrupted.

We provide emergency maintenance, predictive maintenance, and preventive maintenance to ensure production efficiency and equipment stability. By integrating vacuum carburizing process monitoring, potential issues can be identified in advance, reducing unexpected downtime. Preventive maintenance is scheduled based on heat treatment equipment operating hours and predefined service plans, covering all furnace subsystems and components.

Our support covers every aspect of the vacuum carburizing furnace process, from handling multi-alloy and high-alloy materials to the automated generation and execution of carburizing cycles. The heat treatment system is designed with flexible hardness control technology, allowing customers to customize case depth gradients based on specific production requirements. In certain cases, additional carburizing adjustments may be required to refine surface properties or compensate for processing variations. Our heat treatment equipment supports supplementary carburizing cycles, ensuring that material performance meets the intended specifications while reducing the risk of defects.

Our vacuum carburizing control system also supports carbonitriding processes, enabling customers to precisely meet diverse material treatment requirements. This heat treatment system provides the flexibility needed to deliver consistent results for specialized applications. We also offer comprehensive global customer support available 24/7, including remote diagnostics, technical consultations, and process evaluations. With an extensive international spare parts inventory, rapid deliveries minimize operational downtime. Customers also benefit from our complete service coverage, including training, equipment installation, remote maintenance, and startup support, ensuring reliable performance and smooth operation worldwide.

We offer comprehensive solutions across the entire vacuum heat treatment and melting processes. Our expertise includes surface modification, precise microstructure control, and advanced metallurgical processes, allowing us to provide customized equipment configurations and integrated heat treatment lines according to your requirements. Our vacuum heat treatment lines are composed of multiple specialized furnaces, such as vacuum annealing furnaces, high-pressure gas nitriding furnaces, vacuum quenching furnaces, low-pressure vacuum carburizing furnaces, vacuum tempering furnaces, as well as cleaning units. These individual heat treatment systems are integrated with automated loading and unloading equipment and operated through a centralized control system, ensuring efficient production for high-volume manufacturing.

A well-designed vacuum carburizing control system is necessary for achieving consistent and reliable results in heat treatment. Our intelligent vacuum carburizing control system is integrated into both individual heat treatment equipment and fully automated production lines. To help customers evaluate its effectiveness, we offer six commitments, each of which can be customized and formally included in technical agreements:

- The intelligent vacuum carburizing control system ensures accurate and consistent carburizing for a wide range of materials, including multi-alloy and high-alloy steels such as 1Cr17Ni2, 1Cr13, 20Cr2Ni4, 18CrNiMo7-6, and third-generation bearing steels (BG801). This capability ensures effective treatment of materials with complex compositions while maintaining stable performance.

- Carburizing parameters are automatically generated based on three inputs: material grade, target temperature, and case depth. There is no need for manual surface area calculations or specialized carburizing engineers, reducing labor costs while maintaining process accuracy.

- Stable operation is maintained even during long-term continuous processing, producing minimal carbon black. Routine maintenance requires only occasional light cleaning, preventing excessive buildup and ensuring uninterrupted production.

- Customizable case-hardness gradients allow carburized layers to be adjusted according to specific performance requirements. This ensures an optimal balance between surface hardness and core toughness, improving durability for a variety of applications.

- In the event of power failures or gas supply disruptions, supplementary carburizing cycles can be applied to maintain process continuity. This function helps reduce material loss and minimizes production risks.

- In addition to carburizing, the system supports carbonitriding treatments, allowing for greater adaptability to different material requirements. This expands the range of achievable properties, including improved wear resistance and fatigue strength.