Industry Applications of Vacuum Heat Treatment Furnaces

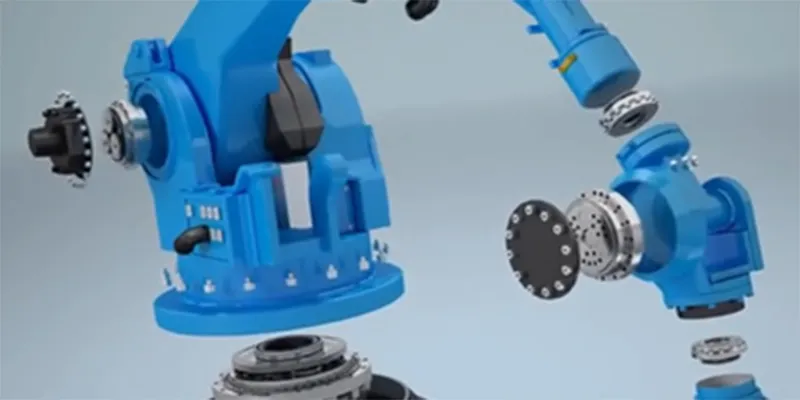

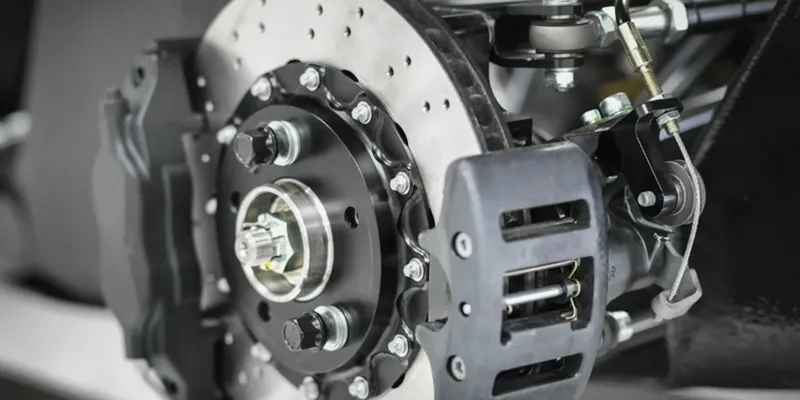

Aircraft engine gears and main shaft bearings require high wear resistance and fatigue strength. To achieve precise control over carburized layer formation and dimensional stability, the aerospace industry relies on low-pressure vacuum carburizing technology. Our vacuum heat treatment solutions have been developed to meet the specific requirements of high-alloy materials used in aerospace applications. Through extensive research, we have refined the carburizing process for high-performance bearings and gears, improving both material quality and processing accuracy. Batch testing results show a significant improvement, reducing prediction errors from 20% to less than 5%, ensuring more consistent and reliable performance.

Components that Can Be Processed

- Hydraulic parts

- Engine components

- Fuel system parts

- Turbine blades

- Jet engine components

- Landing gear assemblies

- Electrical steels

- Aircraft skins and structural components

Case Studies

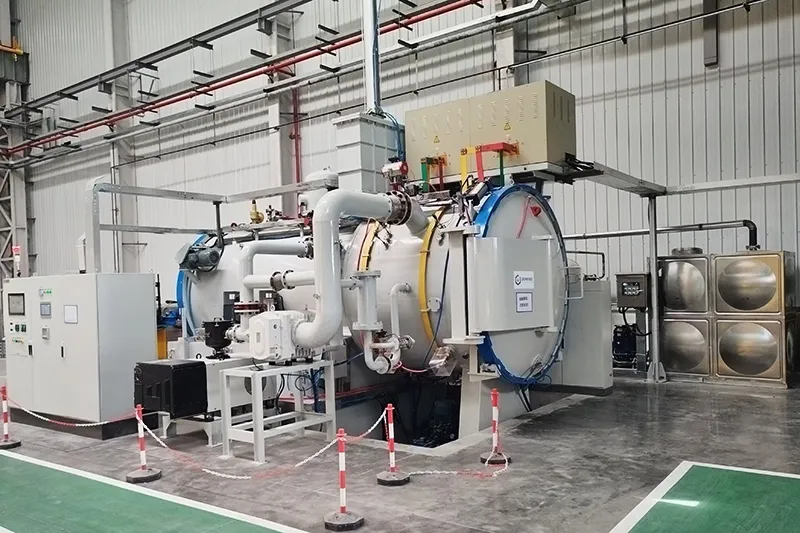

LPC Vacuum Furnace for Aircraft Engine Parts

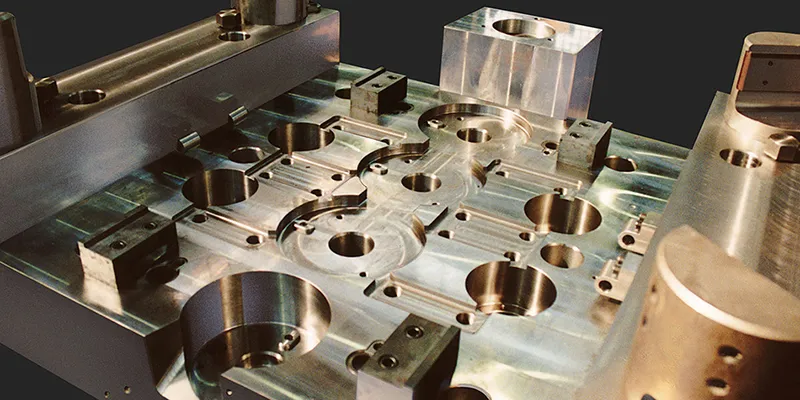

Aircraft engine components, such as gears and spindle bearings, require precise heat treatment due to their exposure to high stress, friction, and demanding operating conditions. To address this challenge, Dongbo worked closely with the Institute of Metal Research, Chinese Academy of Sciences (IMR), supplying a low-pressure vacuum carburizing furnace designed for processing critical engine transmission parts.

See MoreLPC Vacuum Furnace for Aerospace Bearings

Ensuring the durability of aerospace engine bearings isn’t a simple task. These components must handle high rotational speeds, extreme temperatures, and continuous mechanical stress. Any weakness in material properties can lead to performance degradation or even failure. Hence, Harbin Bearing Group Co., Ltd. and Xinchang Jingyi Bearing Co., Ltd. chose our low pressure vacuum carburizing furnace to refine their heat treatment process.

See MoreRecommended Products

-

- Low Pressure Vacuum Carburizing Furnace

- Carburizing prediction error reduced from 20% to 5%, achieving over 95% accuracy

- Minimized carbon black formation for cleaner processes and improved carburizing layer structure

-

- Vacuum Quenching Furnace

- Max. load capacity (kg): 30-1500

- Max. temperature (℃): 1050/1320

-

- Vacuum Sintering Furnace

- Max. load capacity (kg): 200-1200

- Max. temperature (℃): 1600

-

- Vacuum Brazing Furnace

- Max. load capacity (kg): 1000-3000

- Max. temperature (℃): 700

-

- Vacuum Tempering Furnace

- Max. load capacity (kg): 200-1200

- Max. temperature (℃): 750

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555