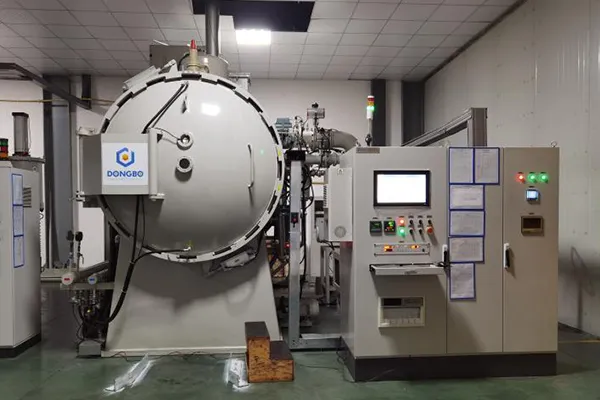

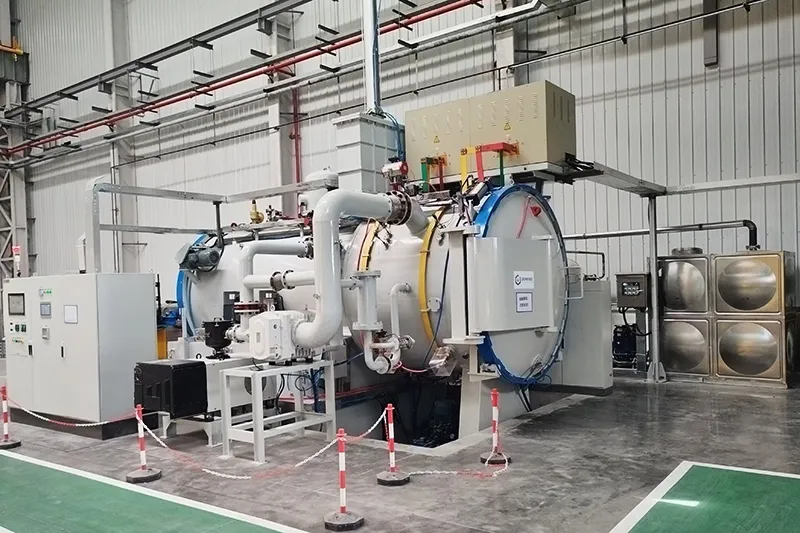

Aircraft engine components, such as gears and spindle bearings, require precise heat treatment due to their exposure to high stress, friction, and demanding operating conditions. To address this challenge, Dongbo worked closely with the Institute of Metal Research, Chinese Academy of Sciences (IMR), supplying a low-pressure vacuum carburizing furnace designed for processing critical engine transmission parts.

The IMR research team focused on developing an optimized carburizing process specifically suited to high-alloy materials. Our furnace provided the precise control needed to achieve uniform carbon diffusion, ensuring stable microstructures and minimal distortion. This method resulted in components that significantly improved their fatigue resistance and surface hardness, meeting the strict quality standards required in aerospace applications.

Extensive testing confirmed the consistency of the carburizing process. Each batch achieved more than 95% accuracy in predicting carburizing depth, while carbide formation and residual austenite levels surpassed industry Class-1 standards. Moreover, compared to imported equipment, the vacuum furnaces we provided successfully reduced prediction error from the standard 20% to below 5%.

This collaborative effort between Dongbo and IMR not only enhanced the performance and durability of aircraft engine components but also established a domestically produced alternative that equals or exceeds international standards. By providing precise, repeatable, and high-quality heat treatment, we support improved durability and consistent performance for critical aerospace components.