RV reducers are widely used in robotic systems and precision machinery, where they must handle continuous stress and high torque. To ensure durability, the gear surfaces need to be hard enough to resist wear, while the core must remain tough enough to absorb impact. Achieving this balance is a challenge in heat treatment, especially for components that operate in high-speed automation environments. After three years of research, we developed hardness gradient flexible control, a process that optimizes the carburized layer of RV reducers. This heat treatment method ensures that over 60% of the hardened surface reaches the required strength while maintaining the necessary structural integrity. This heat treatment process enhances wear resistance and performance stability, reducing the likelihood of premature failure.

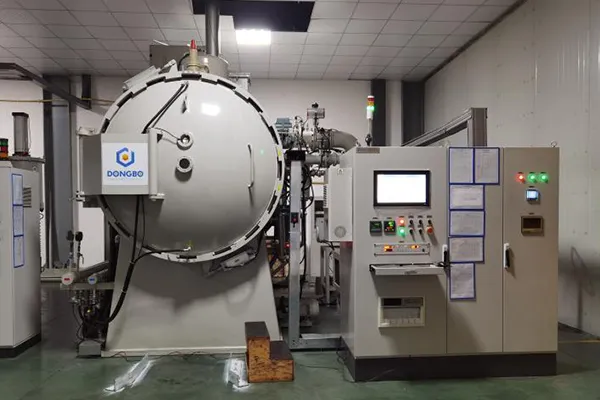

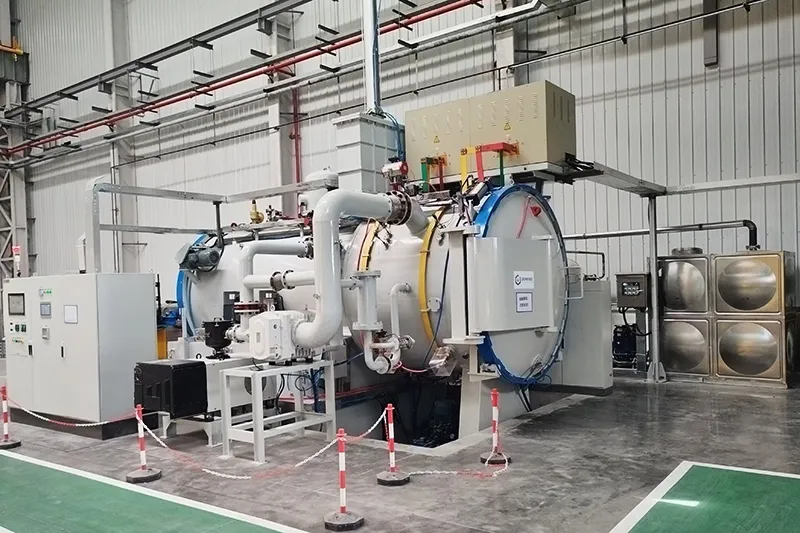

This technology has been integrated into the vacuum heat treatment process at Beijing Chietom Precision Transmission Technology Co. Ltd, a manufacturer specializing in robotic transmission components. The precise control over hardness distribution has resulted in longer-lasting and more reliable RV reducers, essential for industrial robots and automation systems that require consistent and precise motion control.

Our hardness gradient flexible control improves the heat treatment process by enhancing the performance and durability of RV reducers. This advancement meets the growing demands of automation and robotics applications, ensuring reliable operation under high stress and continuous use.