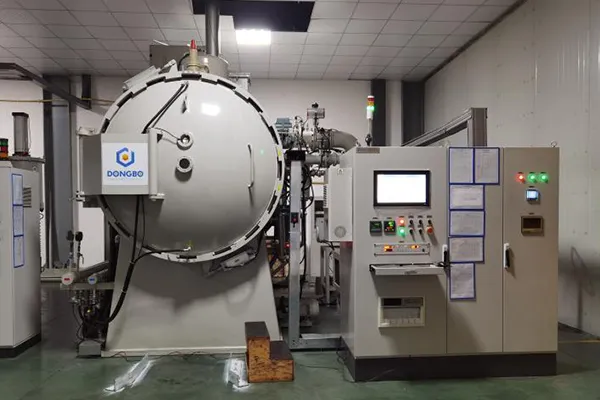

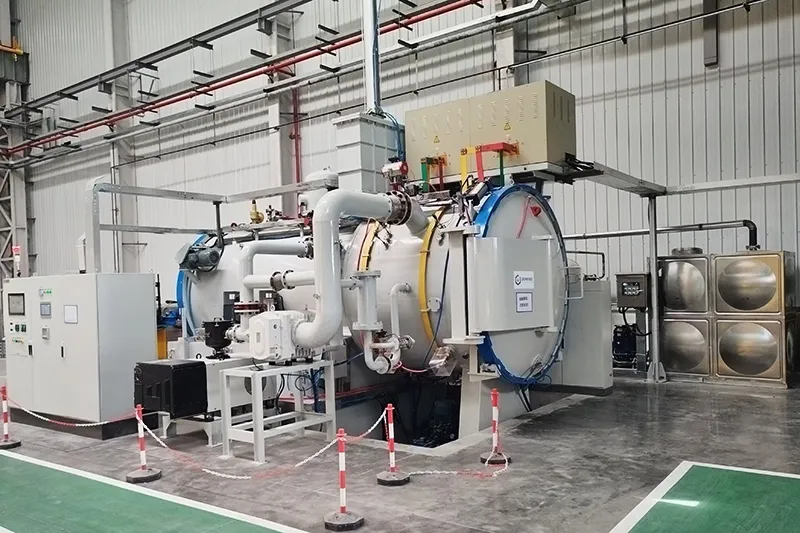

Dongbo developed a low-pressure vacuum carburizing furnace for Jilin Ande Electrification Technology Co., Ltd. to improve the performance of retaining rings and snap rings. These components need to maintain a balance between surface hardness and core toughness to ensure durability under demanding conditions.

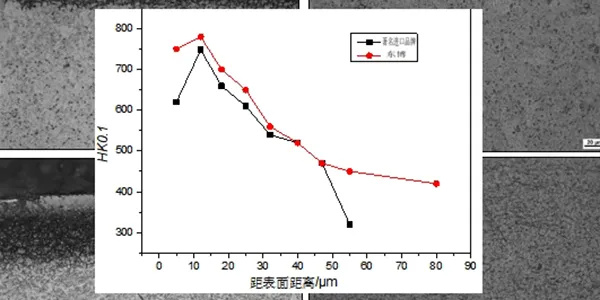

To meet these requirements, we applied a pulse-based carburizing process designed specifically for high-grade stainless steel retaining rings. This heat treatment method enhances wear resistance while maintaining structural integrity. Testing confirmed that the treated rings had precise dimensions, reduced weight, and improved mechanical properties, ensuring reliable long-term use.

One of the most notable results was the increase in pressure resistance. The carburized rings successfully withstood 30MPa, outperforming similar products from international brands. This achievement demonstrates the furnace’s capability to handle complex material processing, enabling the production of components that remain stable under sustained pressures exceeding 5MPa.

Beyond mechanical improvements, the processed retaining rings have been certified by SGS after passing 10 million vibration cycles, 500,000 fatigue cycles, and 30MPa pressure resistance tests. These results confirm that the low-pressure vacuum carburizing furnace provides precise heat treatment control that enhances durability, consistency, and performance in industrial applications.