Industry Applications of Vacuum Heat Treatment Furnaces

Titanium alloys are widely used in defense manufacturing due to their high strength, lightweight properties, and corrosion resistance. However, their surface hardness and wear resistance often require improvement to meet the demands of military and aerospace components. Low-pressure vacuum carburizing is an effective solution for enhancing these properties, increasing durability, and extending the service life of critical parts in aircraft, military vehicles, and defense infrastructure.

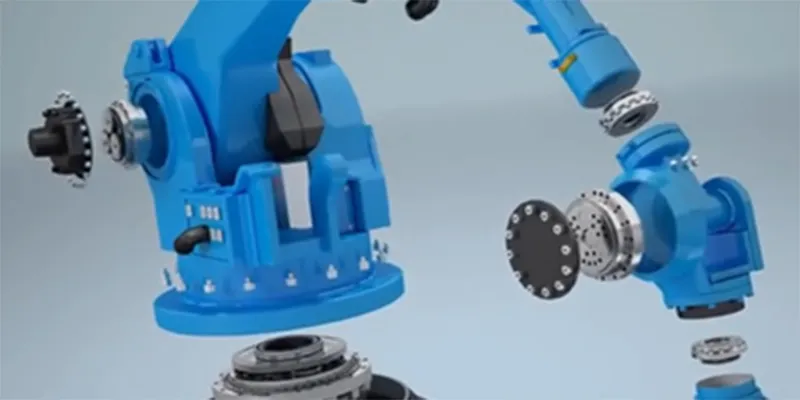

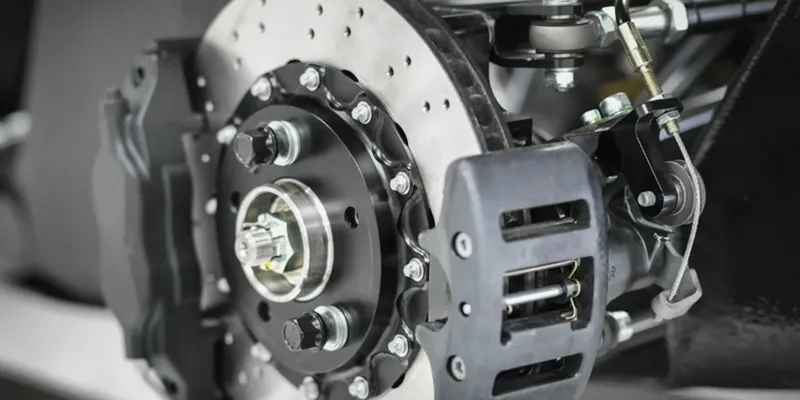

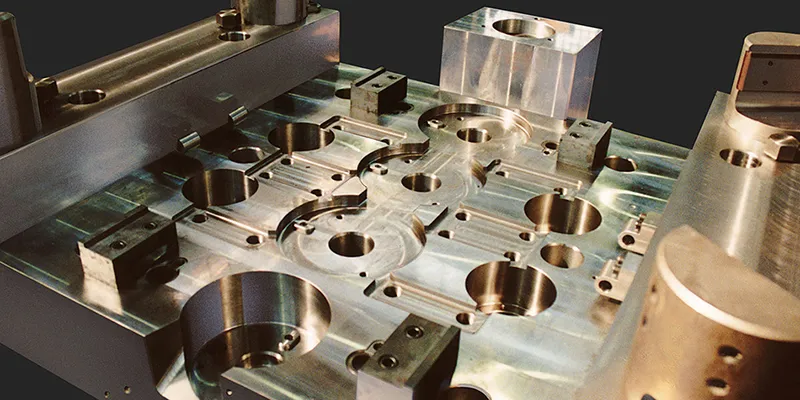

Components Suitable for Vacuum Heat Treatment

- Titanium alloy components

- Armor plating

- Aircraft engine parts

- Gears and gear shafts

- Landing gear components

- Oil coolers and charge air coolers

- Specialized cast materials

Case Studies

Titanium alloys are widely used in high-performance industries, including nuclear energy, aerospace, and defense. While these materials offer low weight, high strength, and excellent corrosion resistance, their low surface hardness and limited wear resistance have been major limitations in expanding their applications.

To overcome these challenges, we developed a low-pressure vacuum carburizing furnace for titanium alloys. Working with China National Nuclear Corporation (CNNC) and Zhejiang Stronger Hydraulic Co., Ltd., this heat treatment technology was designed to enhance surface hardness, wear resistance, and corrosion protection, allowing titanium to be used in more demanding environments.

Recommended Products

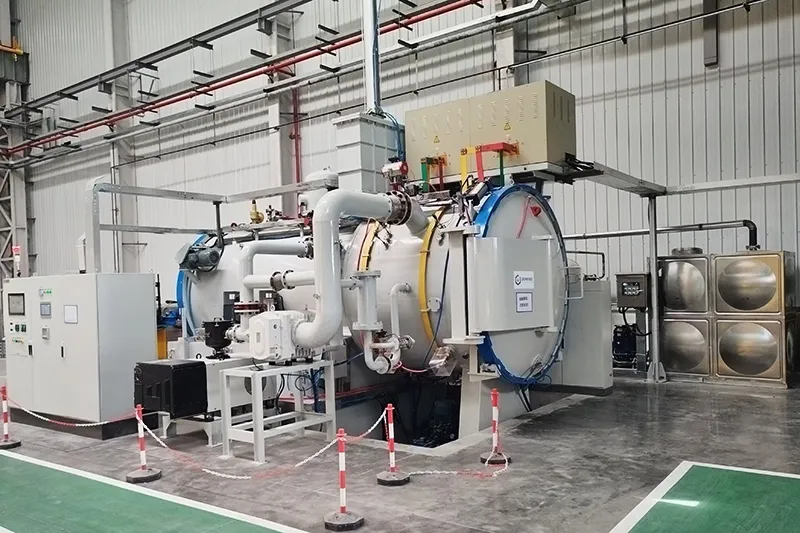

Vacuum Heat Treatment Line

The vacuum heat treatment line integrates multiple processes, such as quenching, tempering, and carburizing, enabling automated and intelligent manufacturing. This system is designed to meet the high precision and performance requirements of the defense industry.

-

- Vacuum Sintering Furnace

- Max. load capacity (kg): 200-1200

- Max. temperature (℃): 1600

-

- Vacuum Brazing Furnace

- Max. load capacity (kg): 1000-3000

- Max. temperature (℃): 700

-

- Vacuum Annealing Furnace

- Max. load capacity (kg): 800-5000

- Max. temperature (℃): 1200

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555