Industry Applications of Vacuum Heat Treatment Furnaces

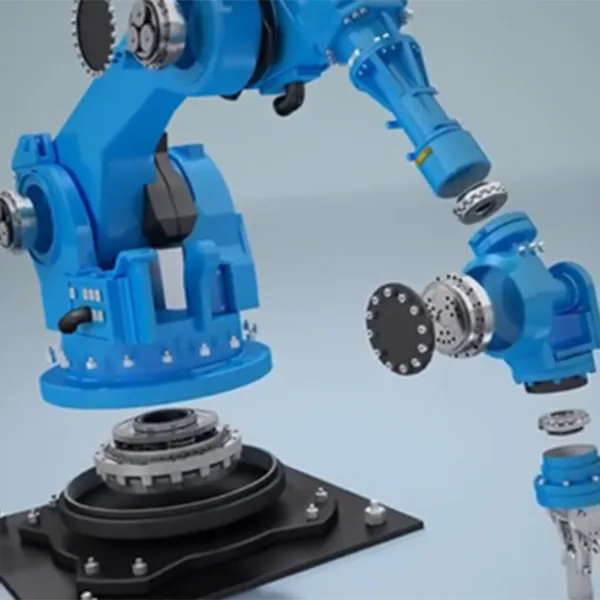

Vacuum carburizing processes improve the performance and durability of key components in industrial robots, including precision reducers, servo motors, and mechanical control elements. These parts are essential for power transmission and motion accuracy. Carburizing enhances wear resistance and fatigue strength, ensuring stable operation and a longer service life.

Features

- Precision reducers determine robotic motion accuracy, stability, and load capacity. Low-pressure vacuum carburizing increases surface hardness and wear resistance, ensuring durability under continuous operation.

- Servo motors rely on strong, fatigue-resistant shafts and gears to drive robotic joints. The carburizing process improves wear resistance and extends the lifespan of these components, reducing mechanical failures.

- Mechanical control components experience greater durability as carburizing strengthens the moving parts in robotic systems. This helps maintain smooth operation, reduces maintenance, and ensures consistent performance over time.

- Vacuum carburizing improves energy efficiency by reducing consumption compared to conventional heat treatment methods. Lower emissions and minimal material waste make it a more sustainable option for industrial robotics.

Case Studies

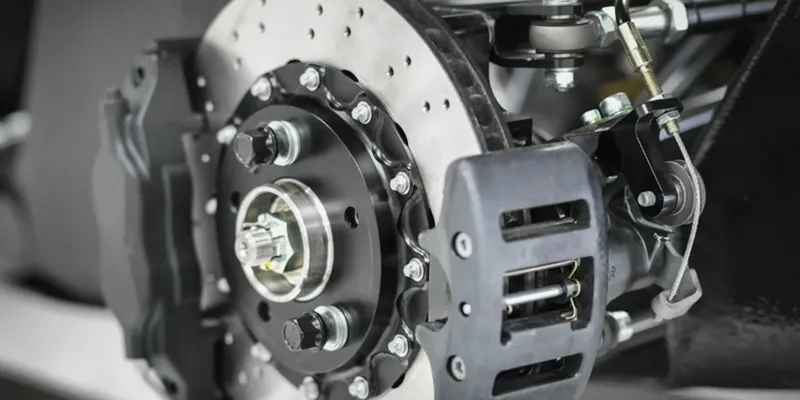

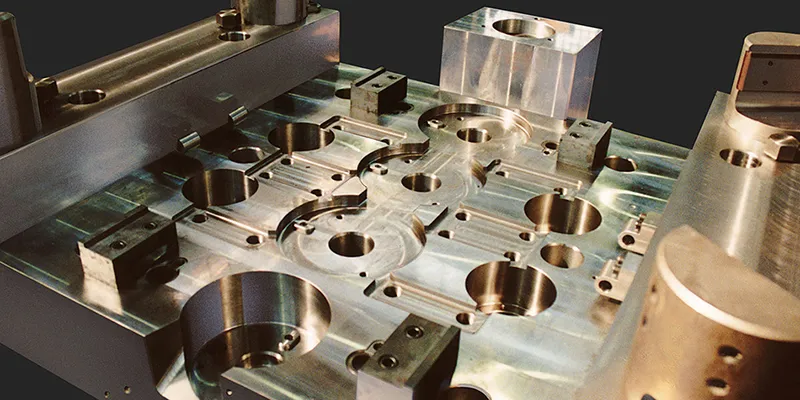

RV reducers are widely used in robotic systems and precision machinery, where they must handle continuous stress and high torque. To ensure durability, the gear surfaces need to be hard enough to resist wear, while the core must remain tough enough to absorb impact. Achieving this balance is a challenge in heat treatment, especially for components that operate in high-speed automation environments.

See MoreRecommended Products

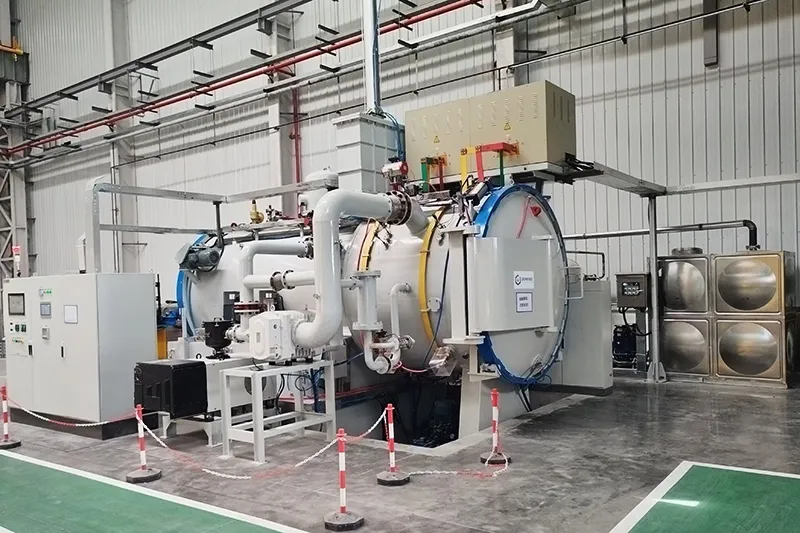

Vacuum Heat Treatment Line

Our vacuum heat treatment production line combines quenching, tempering, and carburizing into a streamlined process. With an advanced control system, it operates without manual intervention, ensuring efficiency and consistency in production. Designed for robotic component manufacturing, this system adapts to various processing needs while improving product quality and operational stability.

-

- Vacuum Brazing Furnace

- Max. load capacity (kg): 1000-3000

- Max. temperature (℃): 700

-

- Vacuum Annealing Furnace

- Max. load capacity (kg): 800-5000

- Max. temperature (℃): 1200

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555