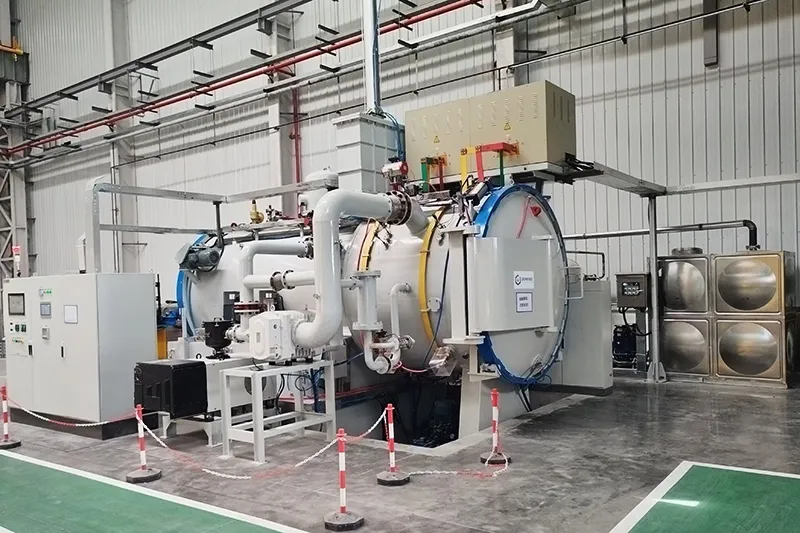

Industry Applications of Vacuum Heat Treatment Furnaces

The power sector utilizes metalworking furnaces for producing essential components like dies, tools, heat exchangers, and pipes. While gas turbine technology is mature, advancements continue, and our contributions are pivotal in the creation of Plate & Bar and aluminum heat exchangers, vital for HVAC and refrigeration, as well as for condensing water vapor systems.

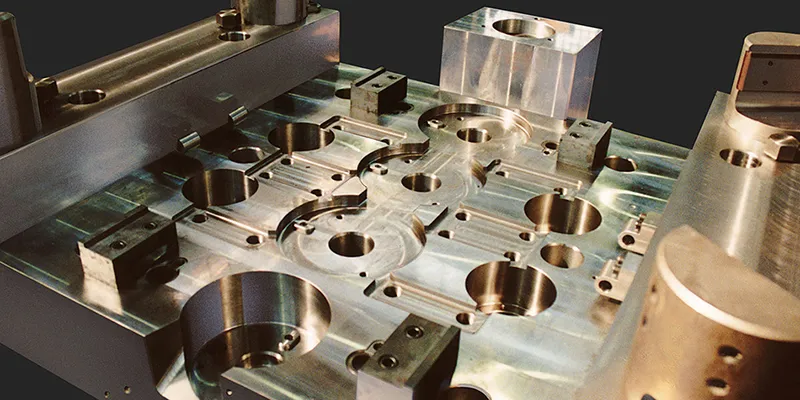

Components that Can Be Processed

- Turbine Blades

- Gears

- Shafts

- Drilling Equipment

- Pumps

- Wire

- Machine Parts

- Electric Power Generators – Radiators

- Heat Exchangers

- Heat Exchanger – Dry Condensing Tubes

- HVAC

Case Studies

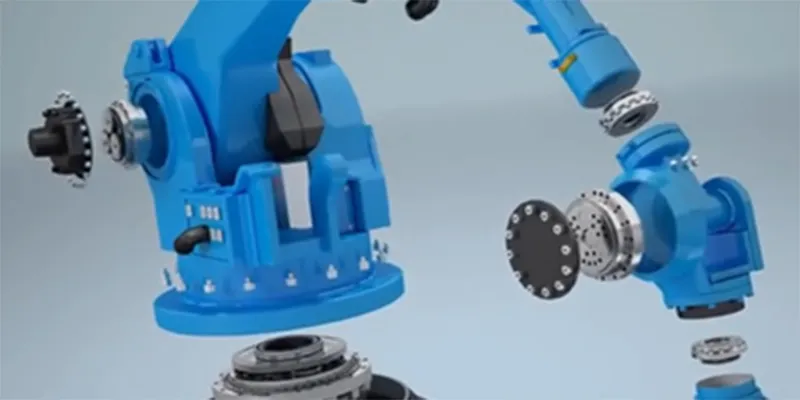

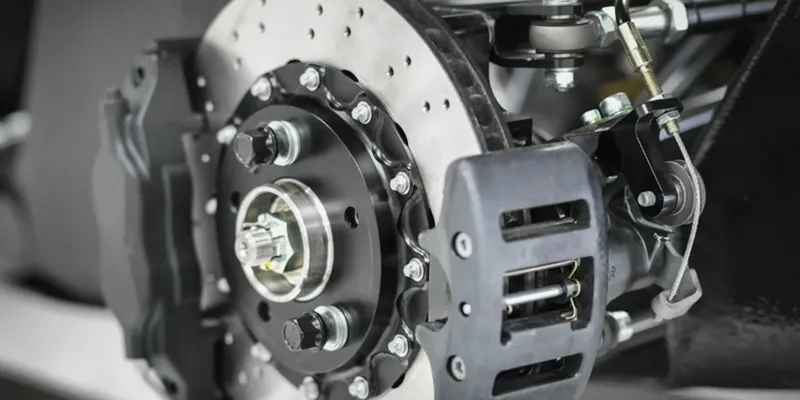

Aircraft engine components, such as gears and spindle bearings, require precise heat treatment due to their exposure to high stress, friction, and demanding operating conditions. To address this challenge, Dongbo worked closely with the Institute of Metal Research, Chinese Academy of Sciences (IMR), supplying a low-pressure vacuum carburizing furnace designed for processing critical engine transmission parts.

See MoreRecommended Products

Vacuum Heat Treatment Line

The integrated vacuum heat treatment line combines multiple heat treatment processes, including vacuum carburizing, high-pressure gas quenching, and tempering, enabling the efficient, flexible, and precise production of critical wind power components. This system meets the high-precision and reliability requirements for components like wind power gears and main shafts, ensuring superior performance and long-term durability in demanding environments.

-

- Vacuum Annealing Furnace

- Max. load capacity (kg): 800-5000

- Max. temperature (℃): 1200

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555