How do the vacuum furnaces ensure safety, environmental compliance, and energy efficiency?

Can the vacuum furnaces reduce operating costs and increase profitability?

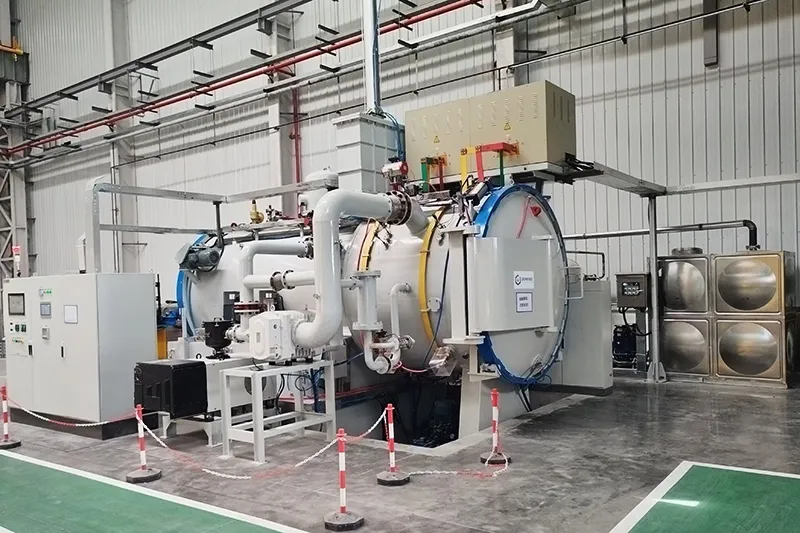

Yes, our vacuum furnaces lower operational costs by reducing energy and atmosphere consumption, while also shortening heat treatment cycles. With a compact footprint and no need for additional auxiliary equipment, they help minimize investment and maintenance expenses. Through software simulation, historical data analysis, and optimized design, our furnaces integrate efficient insulation structures, heating element placement, gas cooling, oil circulation, and water circulation systems, reducing energy loss and maximizing thermal efficiency.

Comparison of energy consumption between vacuum and atmosphere furnaces

| Depth of carburized layer (mm) | Total process time (hours) Time ratio (vacuum/atmosphere) | Total process time (hours) Time difference between vacuum/atmosphere (hours) |

| 0.6 | 5.5/6.5 0.85 | 5.5/6.5 1.0 |

| 0.8 | 5.8/7.5 0.77 | 5.8/7.5 1.7 |

| 1 | 6.5/8.7 0.75 | 6.5/8.7 2.2 |

| 1.2 | 6.9/10 0.69 | 6.9/10 3.1 |

| 1.4 | 7.5/11.5 0.65 | 7.5/11.5 4.0 |

| 1.6 | 8.2/13.2 0.62 | 8.2/13.2 5.0 |

| ... | ||

| 0.6 | 5.5/6.5 0.85 | 5.5/6.5 1.0 |

| 0.8 | 5.8/7.5 0.77 | 5.8/7.5 1.7 |

| 1 | 6.5/8.7 0.75 | 6.5/8.7 2.2 |

| 1.2 | 6.9/10 0.69 | 6.9/10 3.1 |

| 1.4 | 7.5/11.5 0.65 | 7.5/11.5 4.0 |

| 1.6 | 8.2/13.2 0.62 | 8.2/13.2 5.0 |

| ... | ||

| 0.6 | 5.5/6.5 0.85 | 5.5/6.5 1.0 |

| 0.8 | 5.8/7.5 0.77 | 5.8/7.5 1.7 |

| 1 | 6.5/8.7 0.75 | 6.5/8.7 2.2 |

| 1.2 | 6.9/10 0.69 | 6.9/10 3.1 |

| 1.4 | 7.5/11.5 0.65 | 7.5/11.5 4.0 |

| 1.6 | 8.2/13.2 0.62 | 8.2/13.2 5.0 |

How does the vacuum furnace prevent intergranular oxidation (IGO)?

How do the vacuum furnaces improve surface quality, achieving a smooth, silver-white finish?

How do the vacuum furnaces minimize workpiece deformation?

Our vacuum furnaces are engineered to reduce deformation by implementing precise thermal control mechanisms such as:

- Temperature control: Equipped with advanced temperature sensors and regulation systems, ensuring uniform heating to prevent thermal inconsistencies that cause distortion.

- Pressure control: Maintains optimal pressure levels throughout different heat treatment stages, reducing deformation risks.

- Time control: Precisely adjusts heating, holding, and cooling durations based on workpiece material, shape, and dimensions, preventing stress-induced warping.