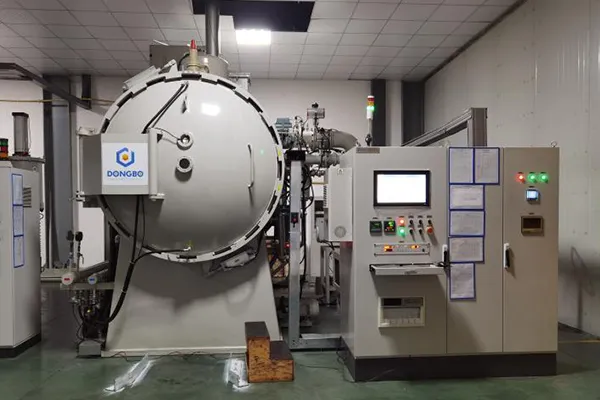

Industry Applications of Vacuum Heat Treatment Furnaces

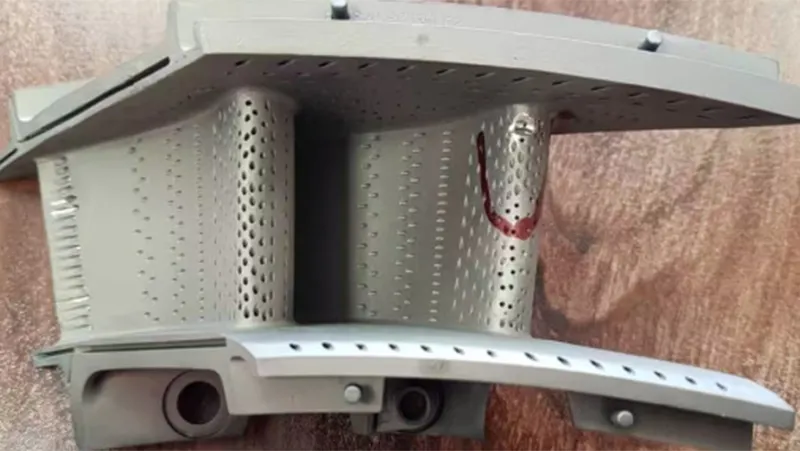

The cooling equipment of X-ray generators is processed using vacuum brazing technology

Materials used in medical implants and surgical instruments require precise heat treatment to ensure their durability, biocompatibility, and resistance to wear. Vacuum heat treatment is used for processing components such as orthopedic implants, vein cleaning tubes, and diagnostic equipment, helping maintain strict industry standards for quality and performance.

Features

- Medical implants and surgical instruments undergo heat treatment to enhance mechanical strength, ensuring they remain durable under repeated use.

- Processing in a vacuum environment prevents oxidation and contamination, maintaining material purity and biocompatibility.

- Precise temperature control ensures dimensional accuracy, which is essential for components used in imaging and diagnostic equipment.

- Heat treatment supports the production of 3D-printed medical parts and advanced materials designed for healthcare applications.

Components that Can Be Processed

- Implants

- Surgical instruments

- Venous catheters

Case Studies

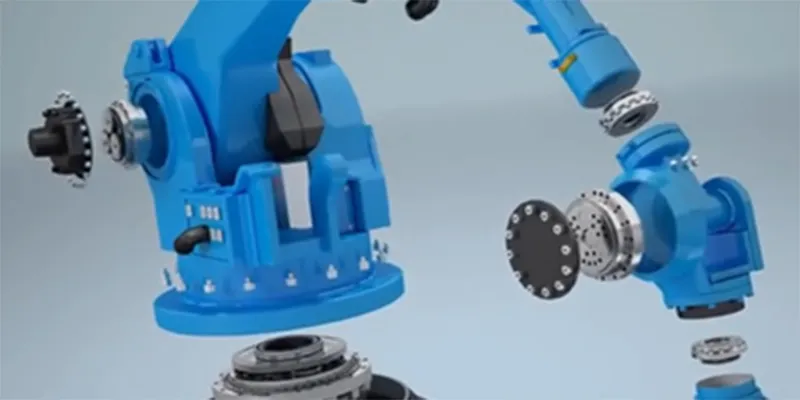

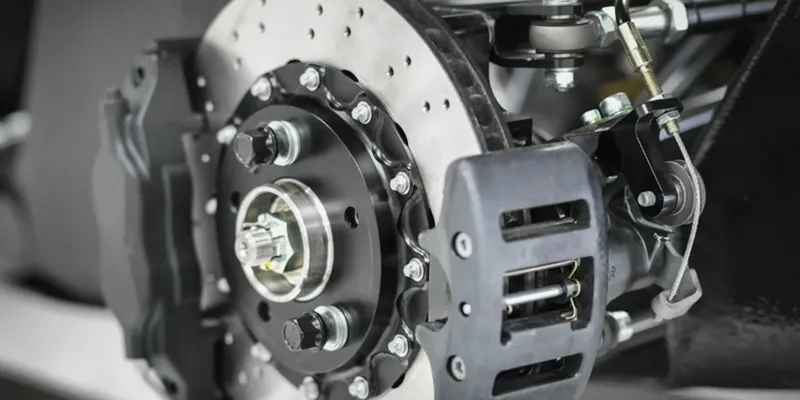

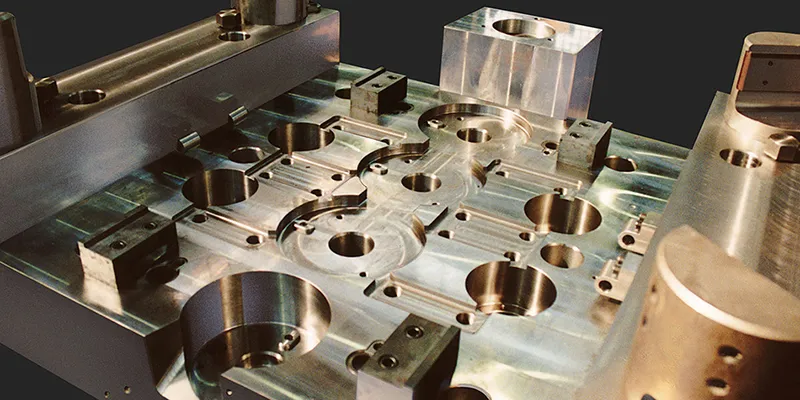

Precision parts manufacturing demands strict material performance, especially for components exposed to constant friction, heavy loads, and repetitive motion. Zhejiang Xunaye Precision Manufacturing Co., Ltd. and Nantong Jucheng Electromechanical Manufacturing Co., Ltd. needed a reliable heat treatment process to ensure their parts met high durability and performance standards. To address this, we supplied a vacuum carburizing and carbonitriding furnace tailored for robotic joints, automotive transmission systems, and power tool components.

See MoreRecommended Products

-

- Low Pressure Vacuum Carburizing Furnace

- Carburizing prediction error reduced from 20% to 5%, achieving over 95% accuracy

- Minimized carbon black formation for cleaner processes and improved carburizing layer structure

Vacuum Heat Treatment Line

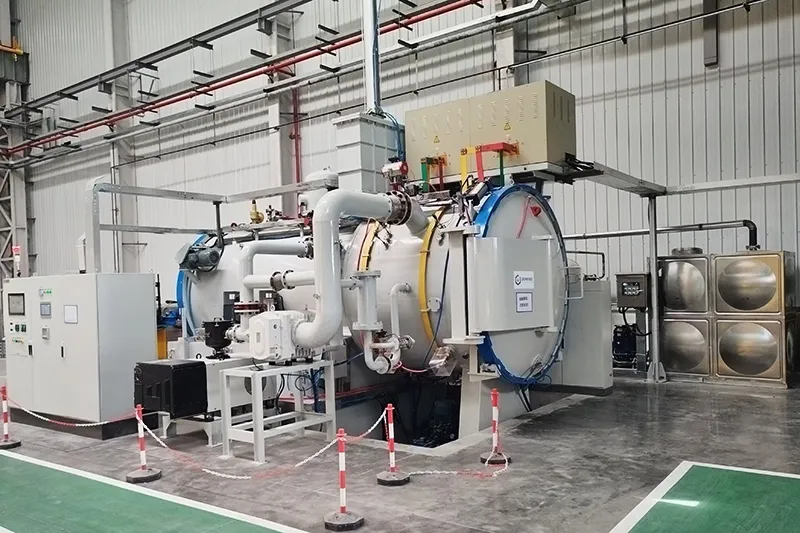

As the demand for medical equipment manufacturing continues to grow, customized vacuum heat treatment lines have become increasingly common. These heat treatment systems integrate multiple processes, enabling automatic and intelligent production. Their ability to process medical implants, surgical instruments, and diagnostic components ensures that manufacturers meet strict industry standards for quality and performance.

-

- Vacuum Quenching Furnace

- Max. load capacity (kg): 30-1500

- Max. temperature (℃): 1050/1320

-

- Vacuum Sintering Furnace

- Max. load capacity (kg): 200-1200

- Max. temperature (℃): 1600

-

- Vacuum Brazing Furnace

- Max. load capacity (kg): 1000-3000

- Max. temperature (℃): 700

-

- Vacuum Annealing Furnace

- Max. load capacity (kg): 800-5000

- Max. temperature (℃): 1200

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555