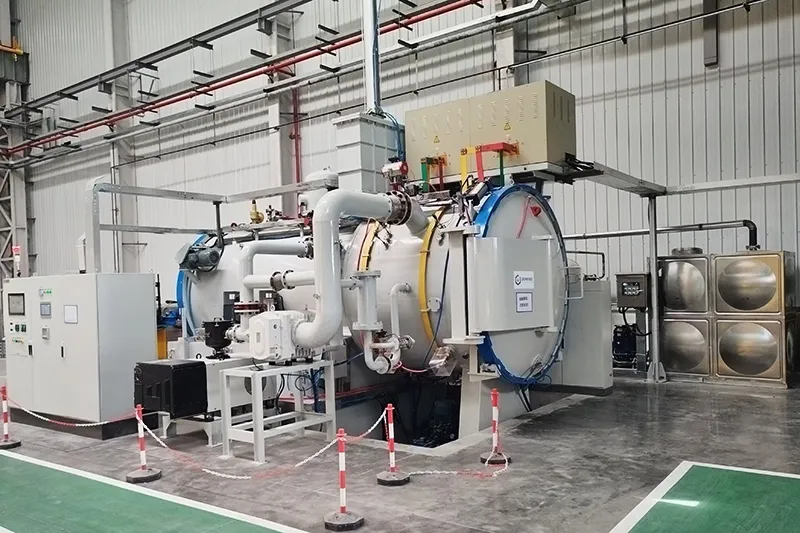

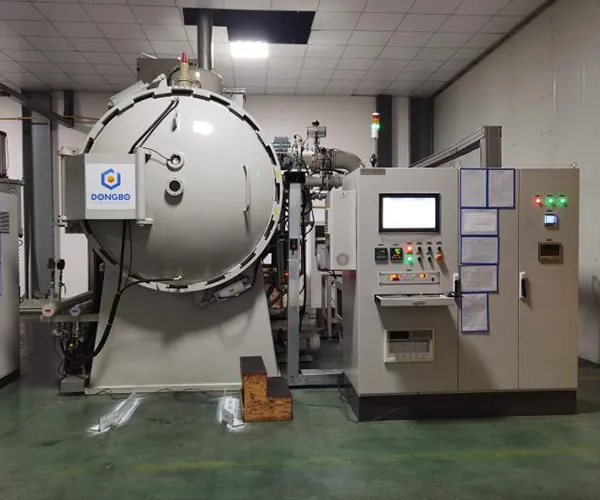

Precision parts manufacturing demands strict material performance, especially for components exposed to constant friction, heavy loads, and repetitive motion. Zhejiang Xunaye Precision Manufacturing Co., Ltd. and Nantong Jucheng Electromechanical Manufacturing Co., Ltd. needed a reliable heat treatment process to ensure their parts met high durability and performance standards. To address this, we supplied a vacuum carburizing and carbonitriding furnace tailored for robotic joints, automotive transmission systems, and power tool components. The heat furnace we offered for this project provides controlled carburizing and carbonitriding, ensuring that hardness transitions smoothly from the surface to the core. A well-balanced heat treatment strengthens the outer layer to resist wear while preserving the toughness needed to withstand mechanical stress.

Through precise control of temperature and diffusion time, both companies optimized their precision parts production without compromising product integrity. The vacuum carburizing and carbonitriding furnace we supplied, has been successfully used to process cycloidal gears, small pinions, and electric tool parts, improving resistance to fatigue and extending component lifespan. With this solution, Zhejiang Xunaye and Nantong Jucheng achieved a more stable, efficient production process, ensuring consistency in every batch while reducing material waste and rework.