Titanium alloys are widely used in high-performance industries, including nuclear energy, aerospace, and defense. While these materials offer low weight, high strength, and excellent corrosion resistance, their low surface hardness and limited wear resistance have been major limitations in expanding their applications.

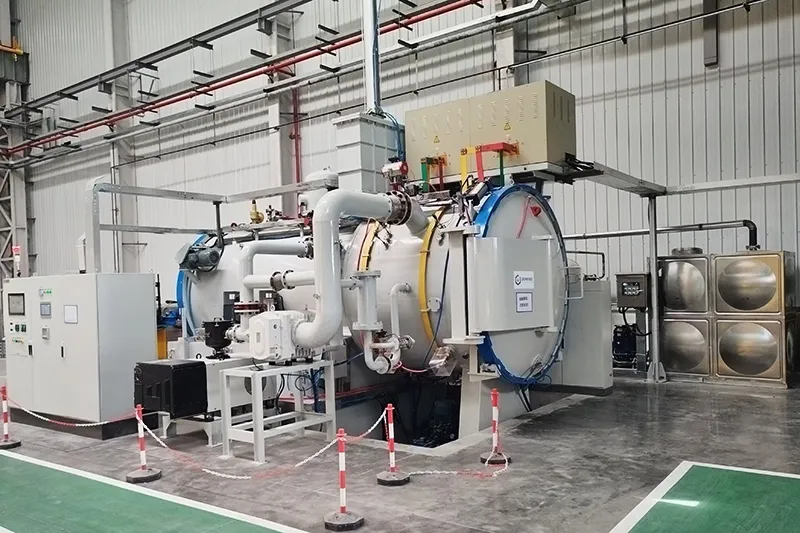

To overcome these challenges, we developed a low-pressure vacuum carburizing furnace for titanium alloys. Working with China National Nuclear Corporation (CNNC) and Zhejiang Stronger Hydraulic Co., Ltd., this heat treatment technology was designed to enhance surface hardness, wear resistance, and corrosion protection, allowing titanium to be used in more demanding environments.

Precise control of the vacuum carburizing process strengthens the surface layer while preserving the toughness of the core material. Adjustments in carburizing parameters make it possible to tailor titanium components for specific operational requirements, improving their durability and resistance to wear. This flexibility allows titanium to perform reliably under intense mechanical and environmental conditions.

With this heat treatment solution, CNNC and Zhejiang Stronger Hydraulic have enhanced the performance and lifespan of their titanium components. The improved surface properties ensure greater reliability in extreme conditions, supporting the increasing demand for stronger and more adaptable materials in industries that rely on precision engineering.