Traditional carburizing methods can be slow and inefficient, especially for large locomotive transmission gears that require deep surface hardening. Tianjin Teek Transmission Co., Ltd. was facing two major issues: long processing times and surface oxidation, both of which increased production costs and affected final product quality.

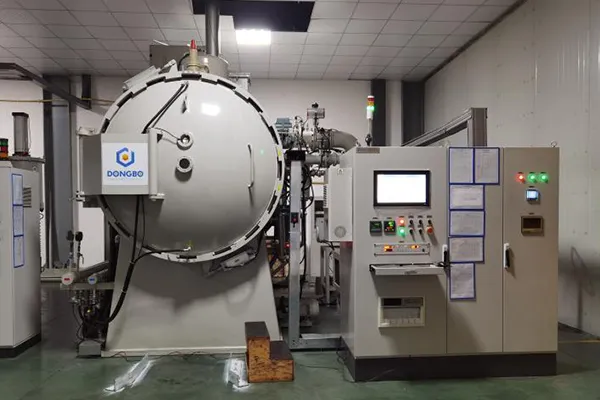

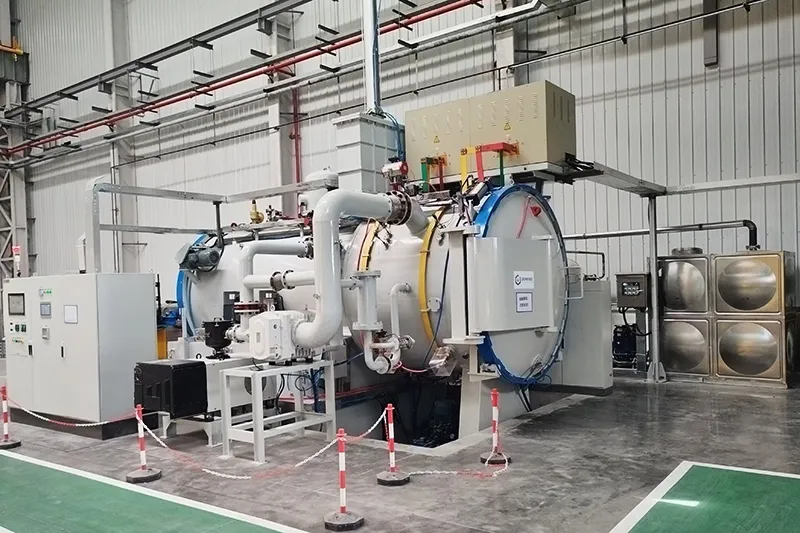

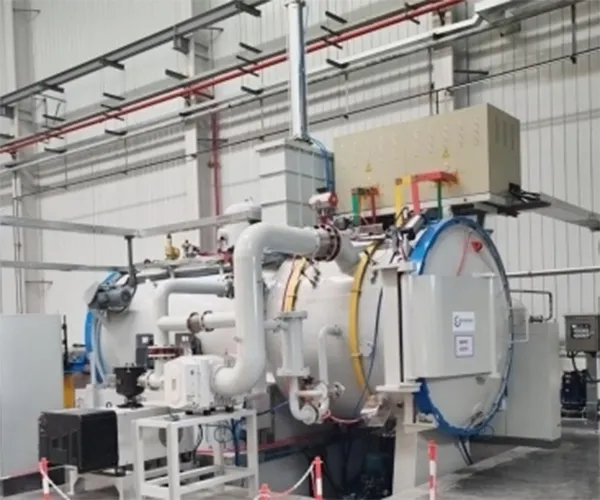

To improve efficiency, Tianjin Teek adopted our High Temperature Carburizing Furnace, developed in collaboration with Northeastern University’s materials research team. This heat treatment system introduced high-temperature carburizing at 1050°C, an approach that transformed the heat treatment process for our client. One of the biggest improvements was the reduction in processing time. The carburizing cycle, which previously took 24.2 hours, was shortened to just 4.3 hours, boosting efficiency by more than 80%. At the same time, performing the process in a vacuum low-pressure environment effectively prevented surface oxidation, reducing the need for additional machining and material removal.

Thanks to this efficient heat treatment technology, Tianjin Teek Transmission Co., Ltd. can now manufacture high-performance transmission gears while maintaining a faster, cleaner, and more precise carburizing process. This improvement ensures that locomotive reducer gears meet both deep carburizing requirements and large-scale production demands, supporting a more efficient and reliable manufacturing process.