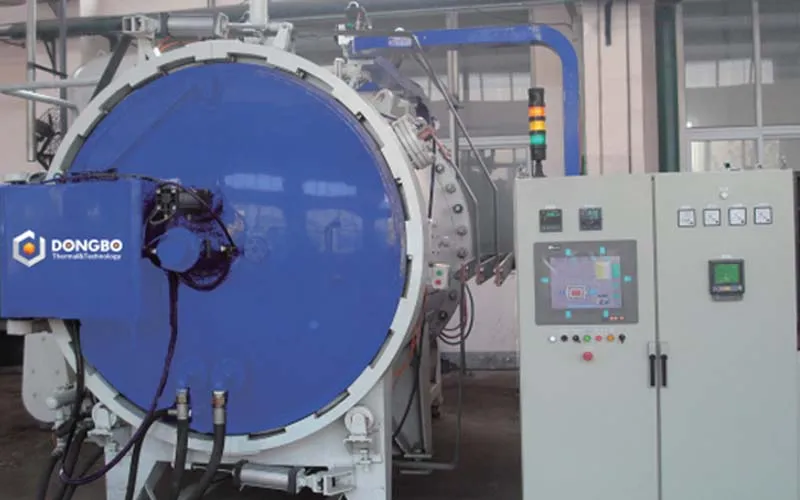

Process Control

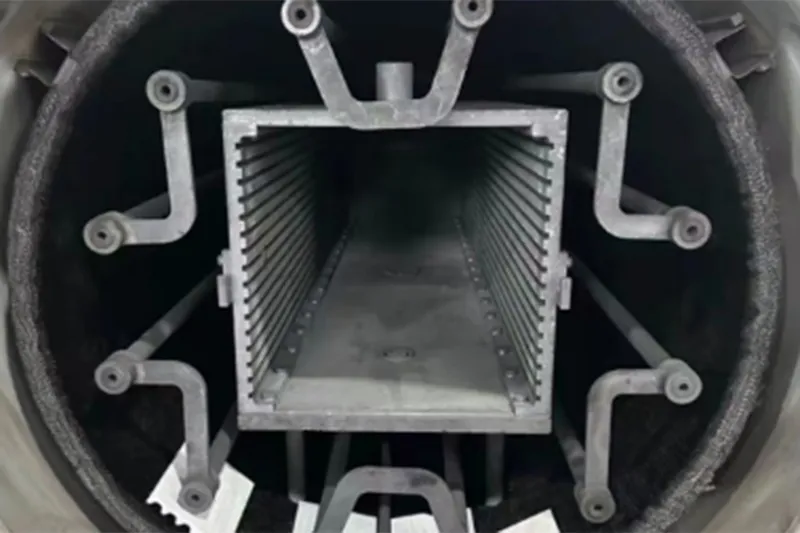

The vacuum environment allows for precise control over carbon content, reducing impurities on the surface of hard phases and improving the wetting behavior between the binder phase and hard phases, resulting in higher alloy strength, particularly in TiC-containing alloys. The process simplifies operations by integrating dewaxing-sintering, reducing oxidation and carbon control difficulties. Its design minimizes equipment footprint and reduces manual labor intensity.

The vacuum heat treatment furnace supports multi-atmosphere dewaxing-sintering with precise control over temperature, atmosphere, and furnace pressure across various temperature stages, achieving isothermal sintering at any temperature. It is also capable of specialized processes like gradient alloy sintering.

Specifications

| Model | DB-SSD644H | DB-SSD755H | DB-SSD966H | DB-SSD1266H | DB-SSD1299H |

| Effective internal dimensions (mm) | 600×400×400 | 700×500×500 | 900×600×600 | 1200×600×600 | 1200×900×900 |

| Max. load capacity (kg) | 200 | 300 | 500 | 800 | 1200 |

| Heating power (kW) | 100 | 130 | 180 | 240 | 360 |

| Max. temperature (℃) | 1600 | 1600 | 1600 | 1600 | 1600 |

| Ultimate vacuum level (Pa) | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ |

| Temperature uniformity (℃) | ±5 | ±5 | ±5 | ±5 | ±5 |

| Max. cooling gas pressure (bar) | 1.99 | 1.99 | 1.99 | 1.99 | 1.99 |

| Pressure rise rate (Pa/h) | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 |

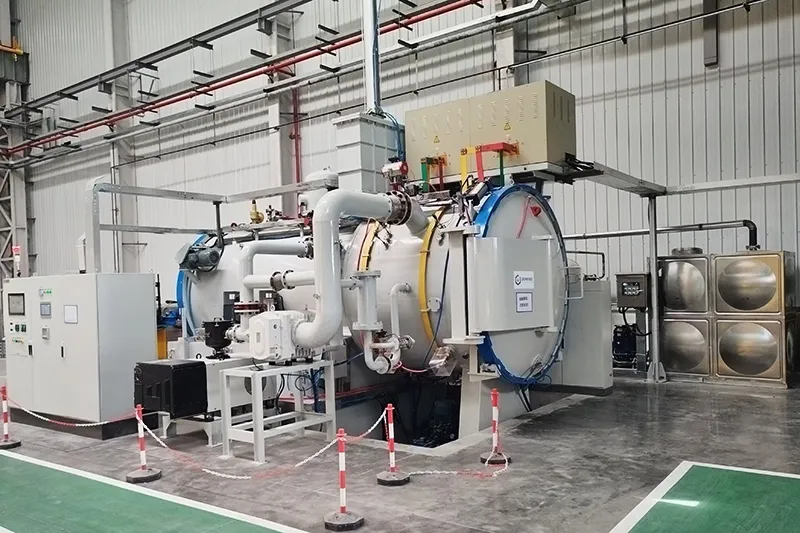

The above parameters are for the standard horizontal single-chamber dewaxing vacuum sintering furnace. We can provide customized, non-standard designs and manufacturing to meet specific customer requirements, such as achieving an ultimate vacuum level of 10⁻⁴ Pa or higher and a pressure rise rate better than 0.1 Pa/h.

Key Advantages

- Provides safe and eco-friendly heat treatment solutions, using clean energy, reducing harmful emissions, and ensuring operational safety.

- Designed for operational flexibility, allowing the furnace to be started and stopped as needed to reduce energy waste and optimize production cycles.

- Ensures high surface quality and minimal deformation during heat treatment, enhancing product reliability.

- Features advanced automation capabilities, reducing manual intervention and significantly improving production efficiency.

- Designed for ease of maintenance and cost efficiency, reducing downtime and operational expenses.