Specifications

| Model | DB VIM-25 | DB VIM-50 | DB VIM-90 | DBAFVIM-DC15 | DB Al-EM15 |

| Furnace structure | Three chamber | Three chamber | Three chamber | Three chamber | Three chamber |

| Capacity (kg) | 15-25 | 15-25 | 60-90 | 10-15 | 10-15 |

| Crystallizer thickness (mm) | 300-400 | None | None | 250-300 | None |

| Melting temperature (℃) | 1700 | 1700 | 1700 | 1700 | 1700 |

| Temperature measurement method | B type thermocouple/ Infrared temperature measurement |

| Feeding method | Vertical / horizontal | Vertical | Vertical | Vertical / horizontal | Vertical / horizontal |

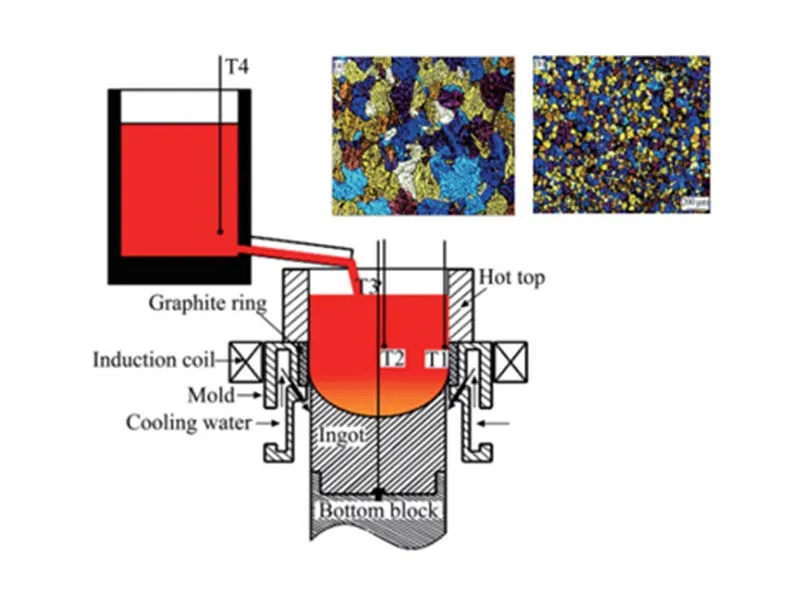

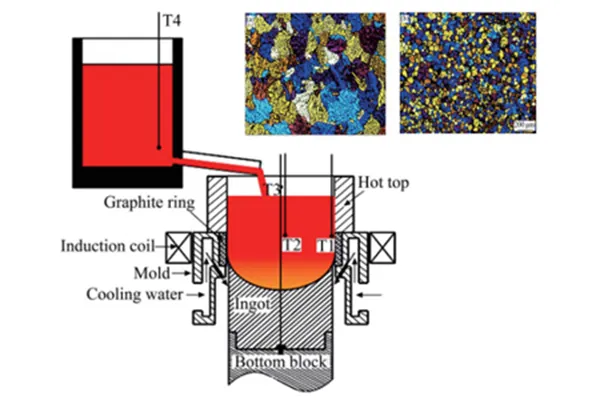

| Heating method | Dual zone induction heating | Induction heating | None | Dual zone induction heating | Induction heating/electromagnetic stirring |

| Insulation temperature (℃) | 1650 | 1500 | 1500 | 1650 | 1650 |

| Ultimate vacuum level (Pa) | 1×10⁻² | 1×10⁻² | 1×10⁻² | 1×10⁻² | 1×10⁻² |

| Pressure rise rate (Pa/min) | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

| Evacuation time (atmospheric pressure to 10pa) (second) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

Features

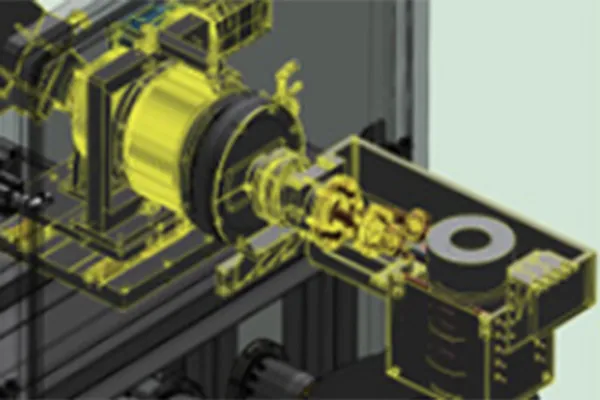

- The EMS precision casting furnace introduces advanced electromagnetic oscillation technology into the precision casting process, significantly enhancing alloy melt fluidity, reducing defects such as shrinkage cavities, porosity, and underfilling, and ensuring the formation of fine-grained structures.

- The electromagnetic oscillation system provides sufficient stirring force during the solidification of the alloy melt, ensuring a uniform cooling process for enhanced structural consistency.

- Designed to match the characteristics of the precision casting process, the system ensures effective implementation of the solidification-oscillation process.

- Features multiple electromagnetic modes, including electromagnetic switching and oscillating coils, allowing for flexible operation and precision in casting high-performance components like turbine blades and impellers.

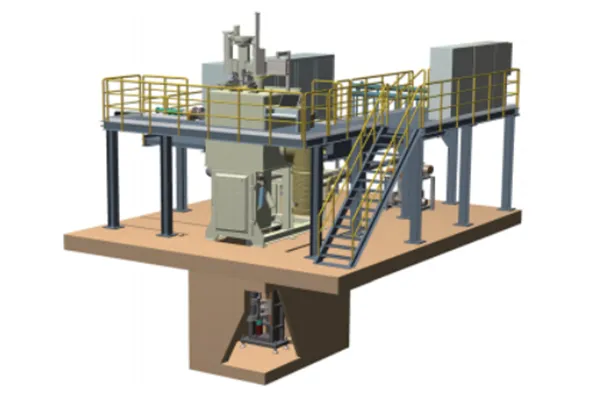

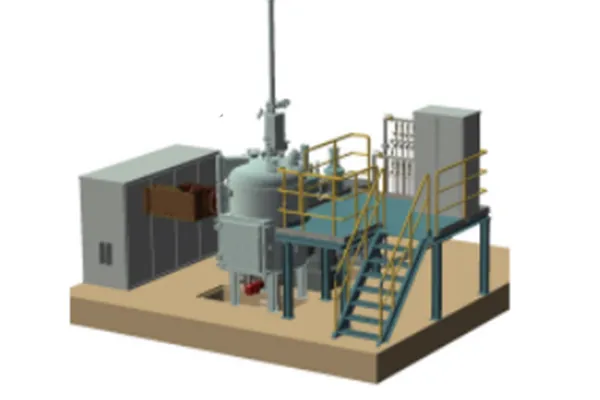

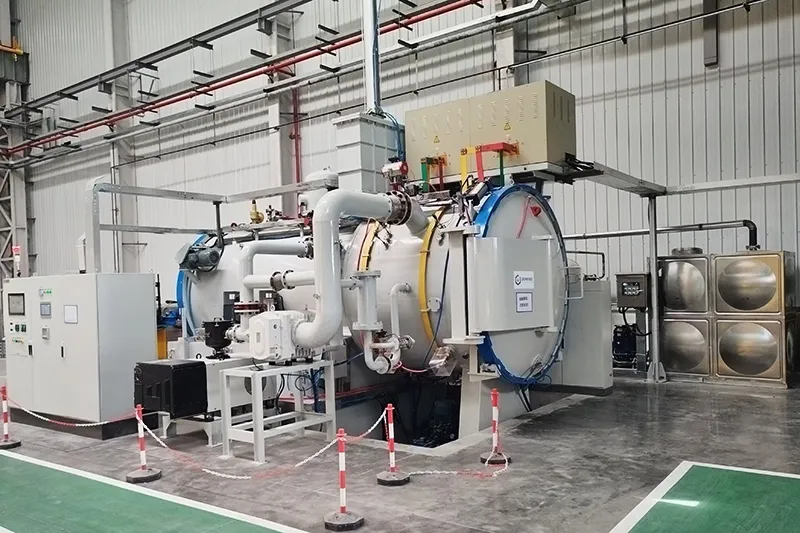

Our Vacuum Metallurgical Equipment