Specifications

| Model | DBAl-VIM-DC15 | DBAl-VIM-DC25 |

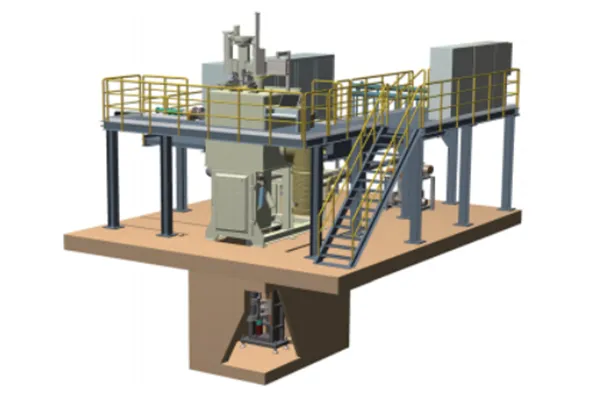

| Furnace structure | Three/four chamber | Three/four chamber |

| Crucible capacity (kg) | 10-15 | 20-25 |

| Melting temperature (℃) | 1700℃ | 1700℃ |

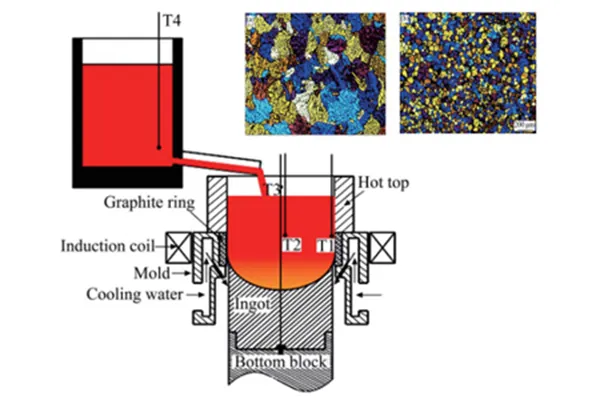

| Dual zone heating | Induction heating | Induction heating |

| Temperature difference between upper and lower zones | ≥60° | ≥60° |

| Crystallizer thickness (mm) | 250/300 | 250/300 |

| Feeding method | Vertical / horizontal | Vertical / horizontal |

| Ultimate vacuum level (Pa) | 1×10⁻² | 1×10⁻² |

| Pressure rise rate (Pa/min) | ≤0.1 | ≤0.1 |

| Evacuation time (atmospheric pressure to 10pa) (second) | ≤60 | ≤60 |

Features

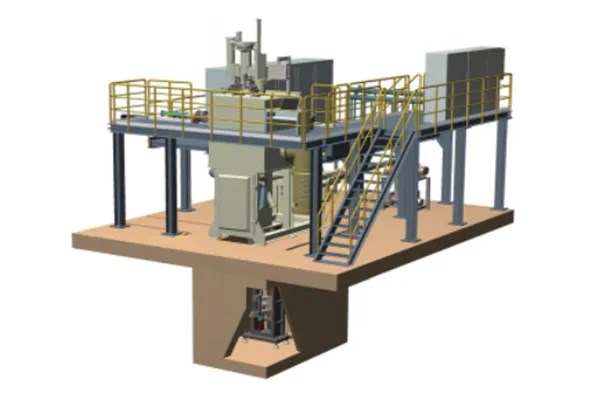

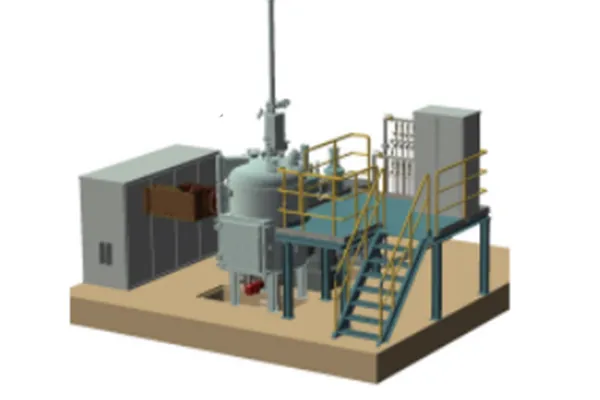

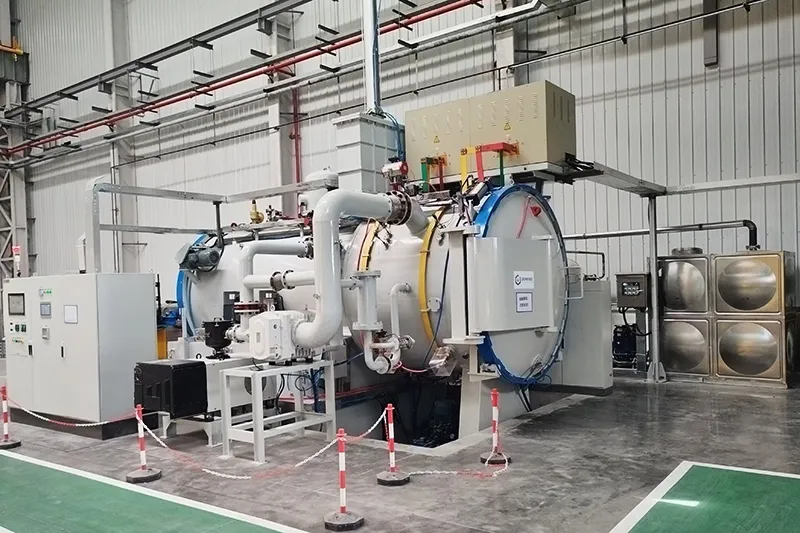

- The furnace adopts a three-chamber vertical layout, designed with mature industrial solutions, advanced construction techniques, and high-standard components to ensure system reliability and durability.

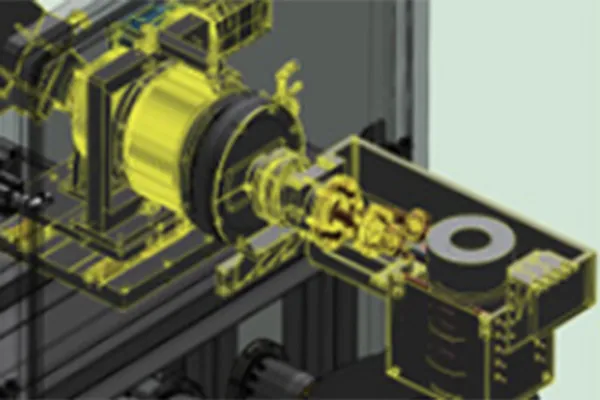

- It addresses key technical challenges such as low-port fixed-point casting for alloy melts, dual-zone induction heating, long-span vibration prevention, and rapid vacuum response, establishing core technologies and functional advantages.

- Equipped with a high-precision simulation platform and an intelligent control system, the furnace supports co-development of equipment and processes for optimized production.

- The system enables real-time production tracking, ensures stable product quality, and allows for customized equipment solutions tailored to specific process requirements.

- Offers online process optimization to improve performance efficiency and accuracy, ensuring superior results for specialized precision casting applications.

Our Vacuum Metallurgical Equipment